About us

We are KRÖNING!

For over 30 years, we have been designing and manufacturing customized special-purpose machines and near-series production systems with passion, precision, and extensive experience. Our core expertise lies in integrating and automating production processes to enhance efficiency and competitiveness.

At our Dohna facility, we develop and produce advanced automation systems for small and medium-sized enterprises as well as major consumer brands and global players.

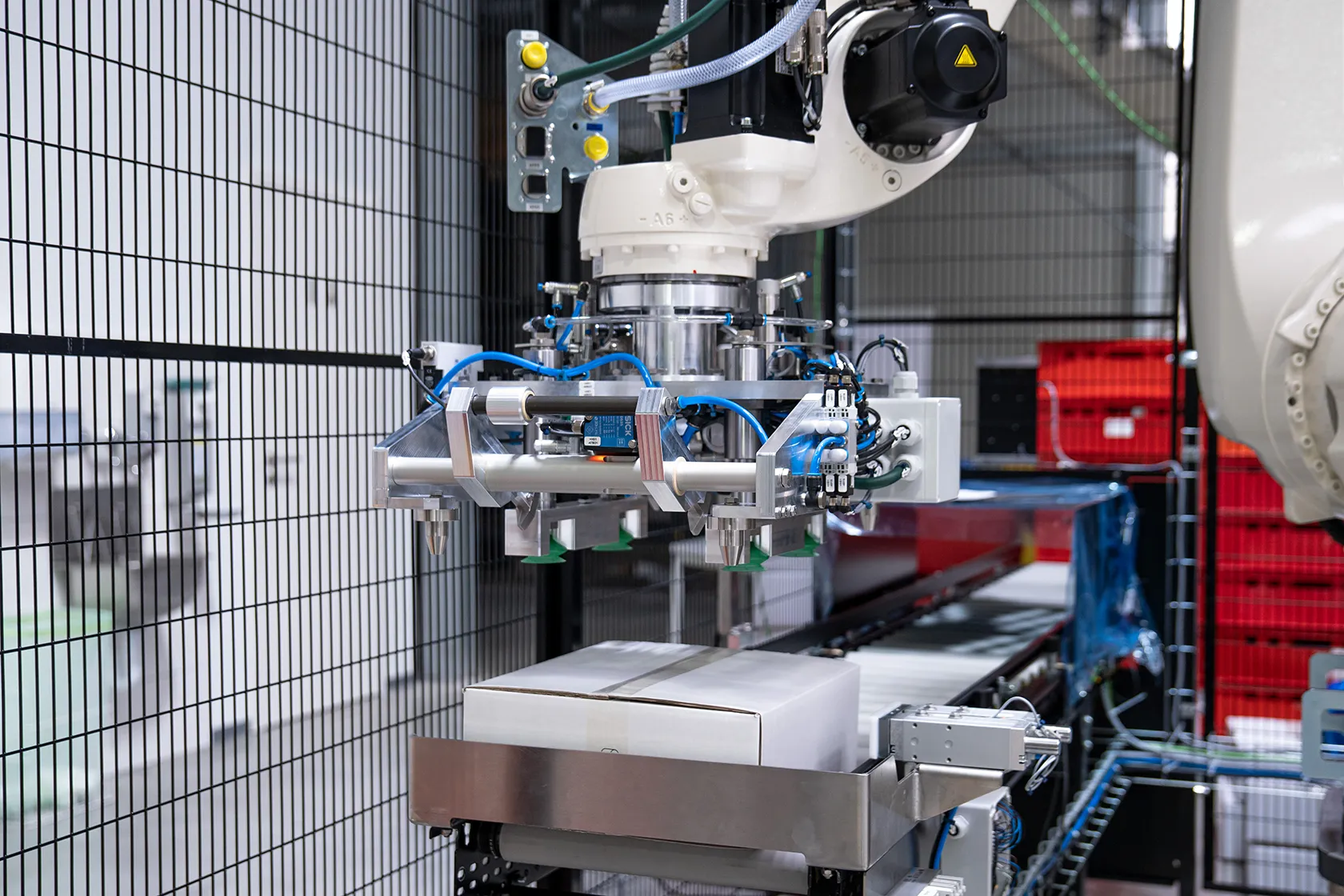

With a team of 70 experts, we implement tailor-made automation solutions – from robotic handling to customized packaging systems.

Whether hygiene-compliant, wash-down design, or high-speed applications – we optimize your production processes and make them future-ready.

We are KRÖNING!

For over 30 years, we have been designing and manufacturing customized special-purpose machines and near-series production systems with passion, precision, and extensive experience. Our core expertise lies in integrating and automating production processes to enhance efficiency and competitiveness.

At our Dohna facility, we develop and produce advanced automation systems for small and medium-sized enterprises as well as major consumer brands and global players.

With a team of 70 experts, we implement tailor-made automation solutions – from robotic handling to customized packaging systems.

Whether hygiene-compliant, wash-down design, or high-speed applications – we optimize your production processes and make them future-ready.

The KRÖNING – Automation team currently consists of around 70 employees based in Dohna, working in project planning, development, manufacturing, software, assembly, and administration to successfully implement customer projects.

We combine the experience of seasoned executives with the innovative drive of our young team members. Our close ties to the Technical University of Dresden – renowned for its excellence in mechanical engineering – play a strategic role in this.

KRÖNING stands for expertise, quality, and durability. With these values at its core, Marcus Kröning continues his father’s company as owner and CEO in the second generation.

By leveraging innovative technologies and a strong commitment to delivering 100% customer value, he is shaping his own path toward the future of automation.

I firmly believe that with our know-how and commitment to quality, we can solve the production challenges of the future.

Marcus Kröning

Founded in 1991 by Thomas Kröning as KRÖNING – Verpackungsmaschinen Service, the company entered its second generation of leadership in 2019 when Marcus Kröning took over—committed to shaping the future of automation.

With this vision in mind, production facilities were doubled, creating space for new ideas and solutions. Today, with around 70 employees, the KRÖNING family continues to grow to meet both customer demands and its own high standards.

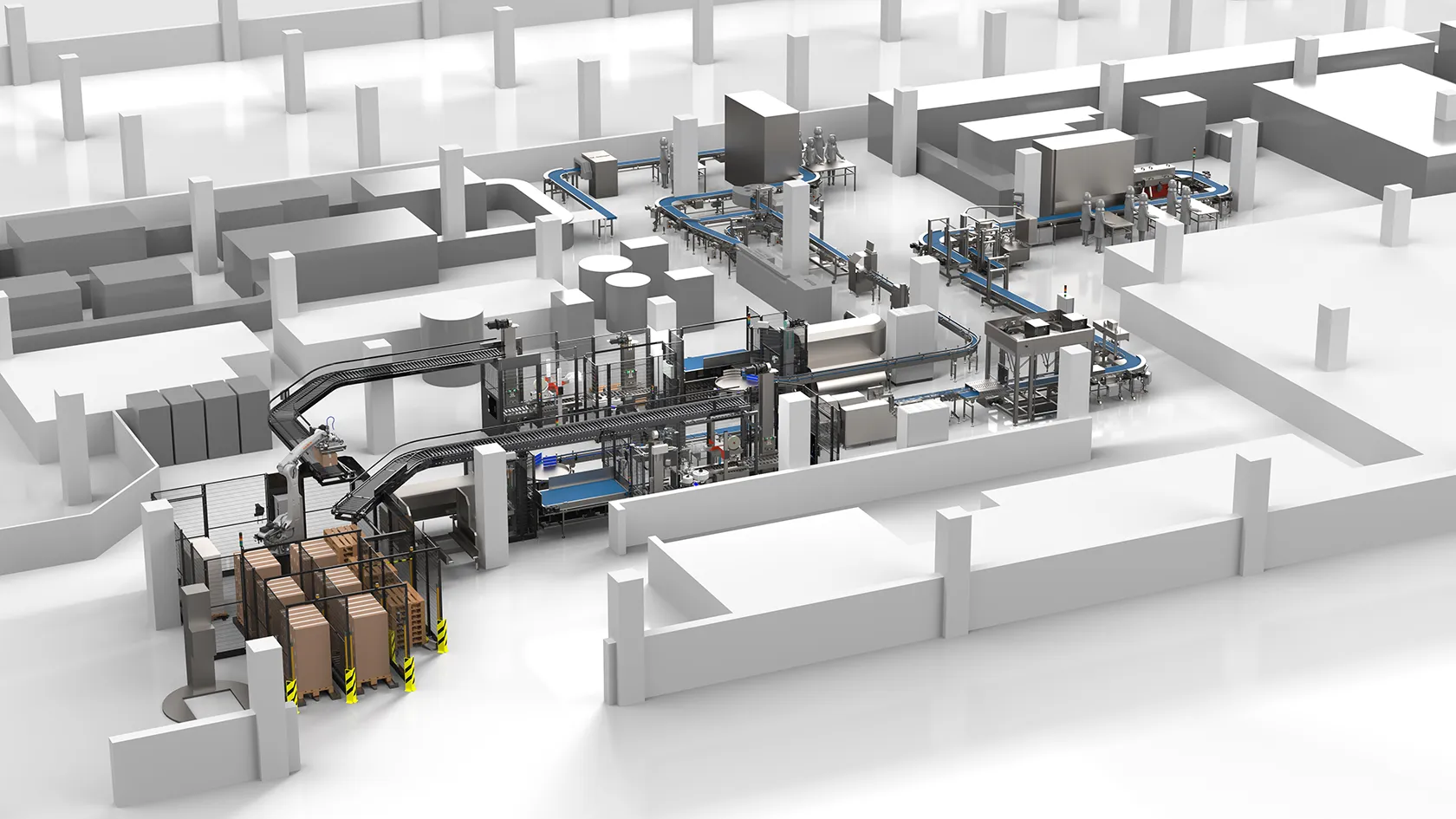

With 4,400 m² of production and office space, KRÖNING offers the ideal conditions to realize even the largest projects at our Dohna site.

Our 1,300 m² assembly hall, equipped with an integrated overhead crane, provides space for systems up to 40 meters in length.

Spacious, modern office spaces ensure excellent working conditions for our employees.

Whether heat pumps or photovoltaics – a sustainable production facility secures the long-term success of our family-owned company.

Passion for Automation

Listen, analyze, evaluate – every project is unique, and we know that. That’s why we focus on close collaboration with our customers. We listen, understand the challenges, and develop solutions together.

And that approach stays the same throughout the entire project. If conditions change – we adapt.

Together. Professionally. Fast.

To remain flexible even in later project stages, control over processes and workflows is key. That’s why we have built up a high level of in-house manufacturing depth.

From planning and design to component manufacturing, assembly, and software development – we cover nearly all project steps in-house.

Project planning

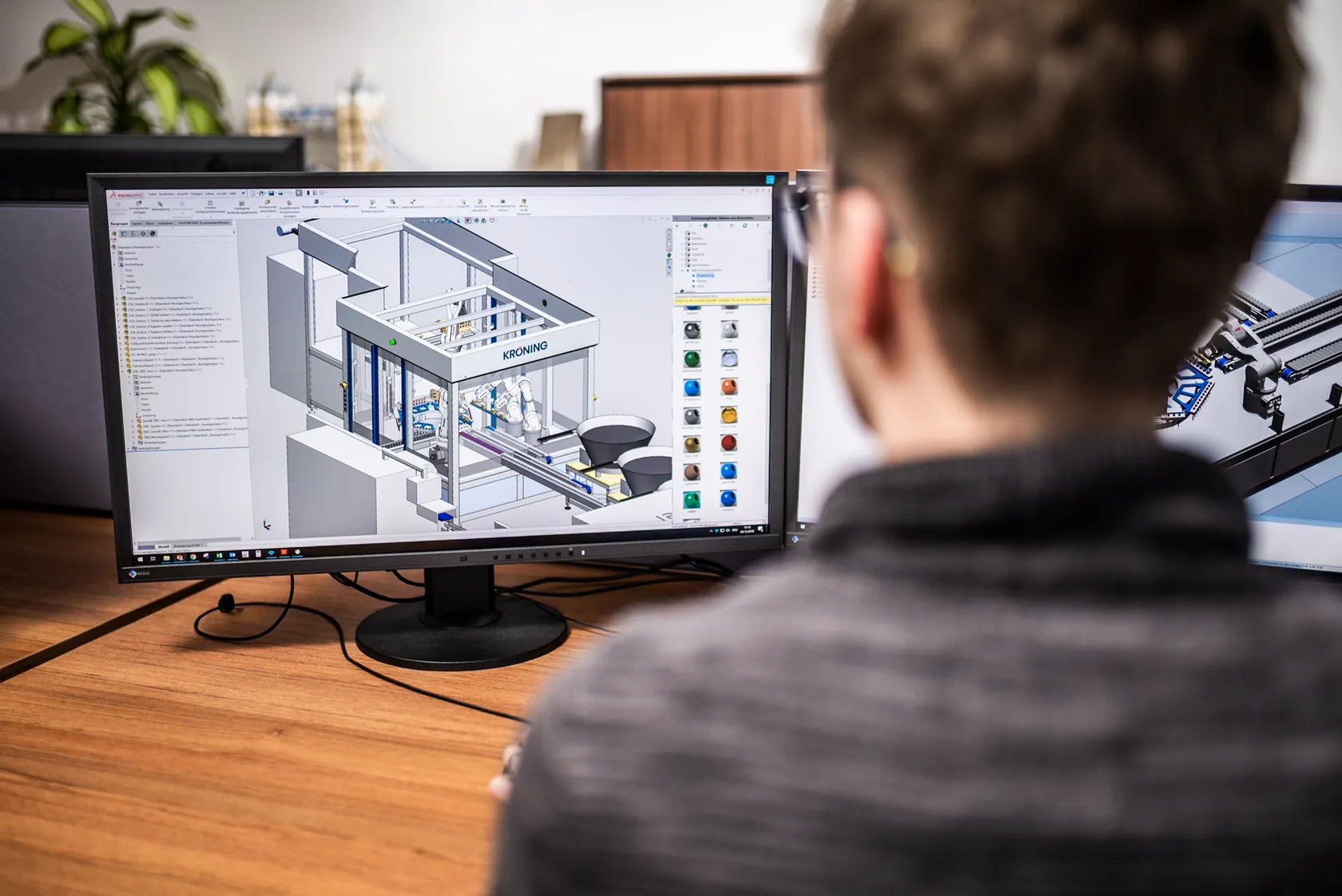

At the start of each project, we develop various technical concepts, visualize them in 3D, and present their advantages and disadvantages.

Through close collaboration, we incorporate your feedback into the planning process and refine the concept to its final stage.

Personal consultation and a detailed presentation of your system using a 3D model are a natural part of our approach.

For every planning stage, we provide you with a tailored offer – including preliminary estimates for your budget planning if needed.

Development

After an initial kick-off meeting, our experienced project managers create a timeline for your project. Our development teams then begin mechanical and electrical design, using software solutions such as SolidWorks and EPlan.

In continuous coordination with you, we conduct several design reviews, during which we explain the system’s design details.

The software development phase also begins in this project stage. In close collaboration with all development teams, our documentation department ensures a smooth knowledge transfer to you.

We provide a detailed breakdown, explaining all the essential components of the system. We are happy to adjust the documentation according to your specifications.

Manufacturing

With over 30 years of experience, we know what can go wrong in a project. That’s why we not only have a reliable network of long-term suppliers but also manufacture many components of your system in-house.

Our own welding shop enables us to produce highly customized frame constructions for your project.

CNC-based manufacturing of metal parts and the use of advanced 3D printing techniques provide the flexibility needed throughout the project.

Control Cabinet Construction

At KRÖNING – Automation, we strive for absolute perfection with maximum individuality. That’s why we handle the control cabinet construction for your system directly in-house.

Our experienced electrical engineers design the ideal control center for your application using the most advanced software solutions from EPLAN.

In-house control cabinet manufacturing allows us to respond quickly to any changes during the project. We make necessary adjustments in close coordination with our assembly and software teams, ensuring no compromises on quality.

Assembly and Programming

Our experienced mechatronics technicians assemble your system at our facility in Dohna. Our assembly hall can accommodate systems up to 40 meters in length.

The software team commissions your system and implements all agreed functionalities.

We respond quickly and customer-oriented to changing conditions. Until final acceptance by you, we thoroughly test the system to ensure smooth production operation.

FAT, Dismantling and Shipping

After customer acceptance of the system, our mechatronics team dismantles, documents, and prepares it for shipping.

Thanks to our excellent transportation links, loading and transport by truck proceed smoothly.

Production Support and Commissioning

Our assembly team receives the system on-site and fully integrates it into your production environment.

The project-leading software engineers make the final adjustments and commission the system at your location.

During the SAT, all critical functions are tested. After acceptance, we support you during production start-up and train your staff on the new system.

Automation for the future

Addressing the current labor shortage is one of the most significant challenges of our time. In this context, integrating automation offers a sustainable solution to compensate for missing workforce and make production future-proof.

This enables a reduced need for personnel while maintaining the same production output.

The scalability of automation lines not only optimizes current production but also creates a future-proof foundation to support expansion to a 3-shift operation or personnel-free night shifts.

Employee Relief

In production environments, employees face the challenges of monotonous, heavy, and hazardous tasks. Here, automation provides an optimal solution to relieve employees and free up capacity for other areas of work.

By using robots, repetitive tasks such as packaging products can be efficiently handled.

Palletizing robots help load heavy cartons for shipping, supporting the physical relief of employees. In the chemical industry, specialized handling robots are used to protect employees from hazardous substances.

These innovative technologies actively enhance employee safety and health, leading to improved working conditions in the long term.

Consistent Quality

Automation lines offer unmatched repeatability, ensuring that product quality remains consistently high, regardless of production speed.

This is especially beneficial for sensitive products, ensuring better shelf life.

Automated applications also reduce downtime and are independent of fluctuating workforce capacities, which can significantly increase productivity.

By optimizing production processes, resources can also be saved.

Long-standing suppliers

Quality and durability define our claim – for our customers, for ourselves and also for our suppliers. With over 30 years in the market, we have built up numerous strategic partnerships for all areas of our machines.

As a customer, you benefit from increased availability, reliable quality and unlimited product know-how.

- ABB, Stäubli, KUKA, Autonox

- Keyence, Sick, Leuze, Pilz

- Siemens

- Flexlink, Interroll

- Festo

- Wipotec

- Geia

- Niedax

- Rittal

- SEW Eurodrive

- Neugart

- Axelent

- Bosch Rexroth

- LinMot

- Schmalz

- Robatech, Nordson

- Cognex

- IFM

- Schunk

Strong partners

Every application has its specialists – with our partners in series machine construction, we integrate proven systems into our plants. The long-standing partnership is reflected in seamless cooperation throughout the entire project.

You benefit from lower prices, proven machines and first-class service.

- Stäubli

- J+P Maschinenbau

- Lantech

- Fuji Packaging

- Prewa

- Variovac

Reliable OEM

We are specialists when it comes to the unusual – and that is something that series manufacturers are aware of. That is why we have been used as an OEM for packaging suppliers on numerous occasions.

- Syntegon

- Bühler Group

- SCHUBERT Group

- Theegarten-PacTec

- ROVEMA

More engineering power

To ensure that we always offer you the best possible design quality, we at KRÖNING – Automation can draw on our group of companies.

You benefit from more engineering power without more effort.