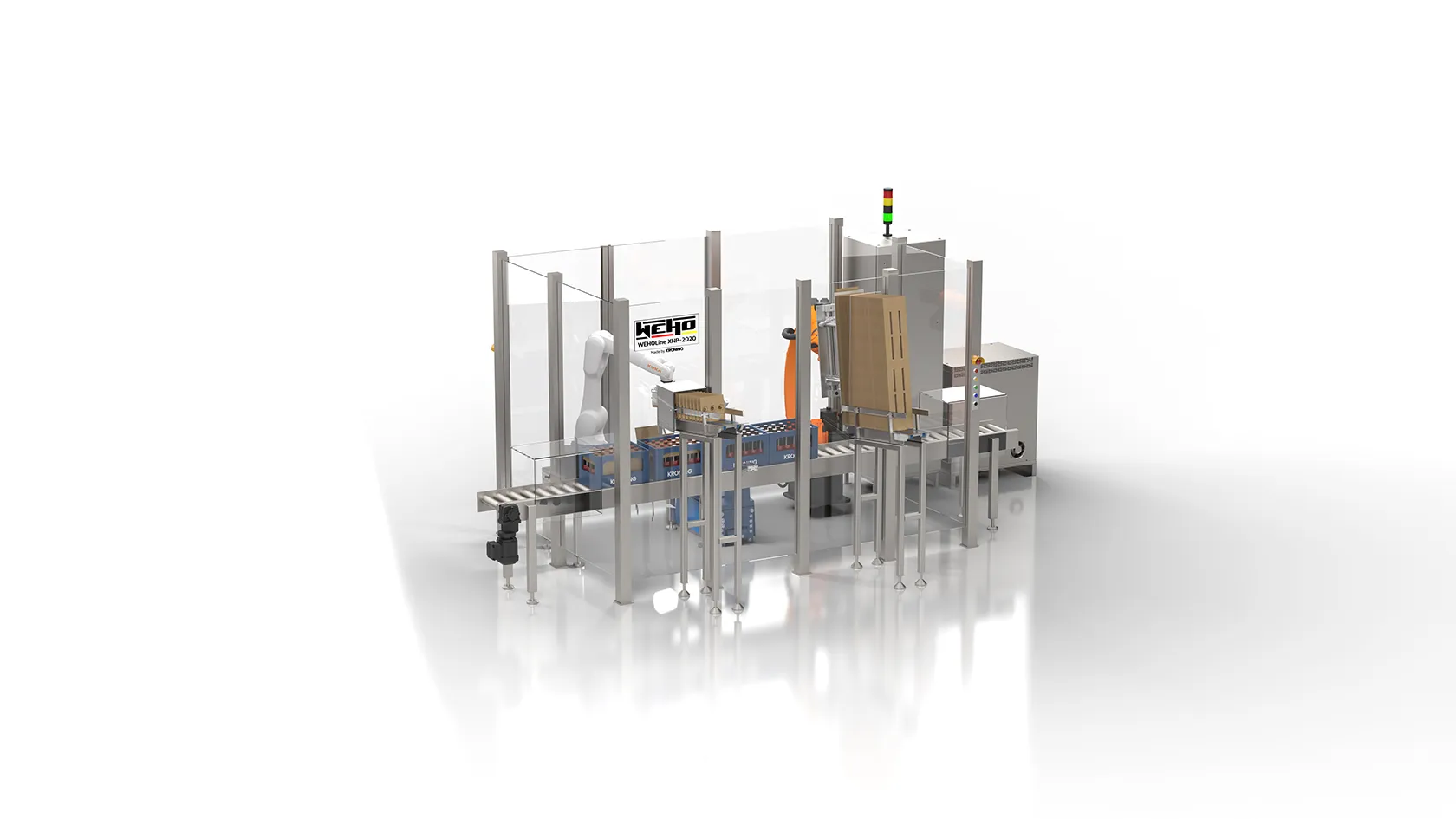

WEHOLine by KRÖNING

Packaging line for six packs

WEHOLine by KRÖNING

| Task | Packaging and inserting six-packs of beverages into crates |

| Size | XS – XL |

| Industry | Beverages |

| Main function | Moving, packaging, others |

| Interfaces | |

| Degree of customization | Series |

WEHOLine® L

- 48 packs/min.

- Fully automatic solution

WEHOLine® M

- 10 – 12 packs/min.

- Fully automatic solution

WEHOLine® S

- 10 – 12 packs/min.

- 2 – 3 operators

WEHOLine® XL

- 48 packs/min.

- Fully automatic solution with mixed packaging

WEHOLine® XS

- 2 – 3 packs/min.

- 1 operator

WEHOLine® XS

The smallest system configuration offers the perfect entry into packaging automation with WEHO®Pack, especially for small production volumes.

- One operator loads the system with unfolded clusters, bottles and clips.

- Automated gluing and attachment of the packaging at the push of a button.

- Loading of 2 – 3 packs per minute.

- 1 operator

The right choice for medium production volumes and small budgets.

- Unfolding of the WEHO® cluster and insertion of the bottles by one operator

- Automatic application of the WEHO® clip and gluing to the cluster

- Packaging of the finished bundles in the crates by one operator

- Filling of 10-12 packs per minute

- 2 – 3 operators

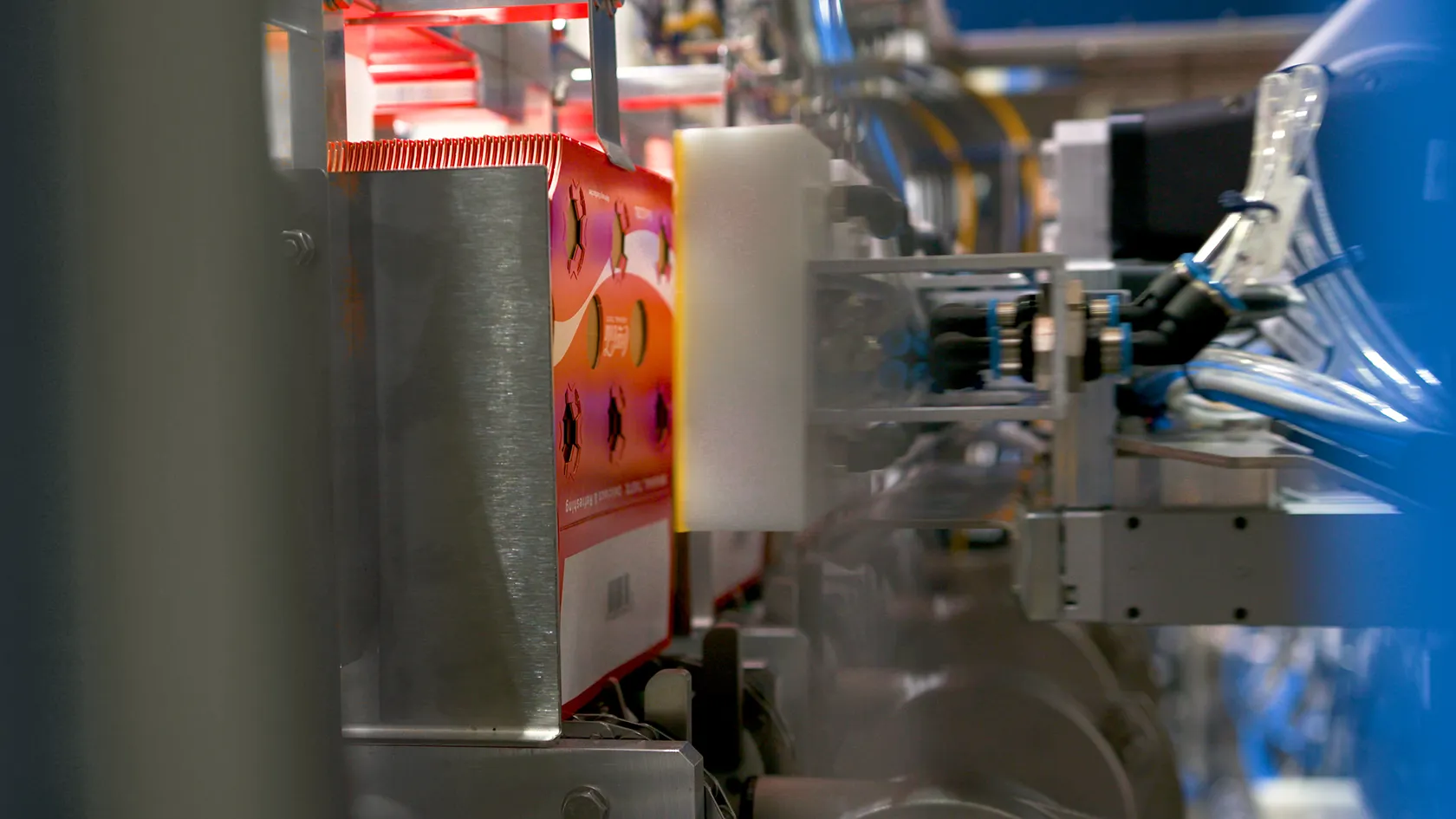

Fully automatic solution for high production volumes

- Single-track feeding of the filled crates into the system

- Automatic unfolding of the WEHO® cluster for formats without a central bridge from a magazine

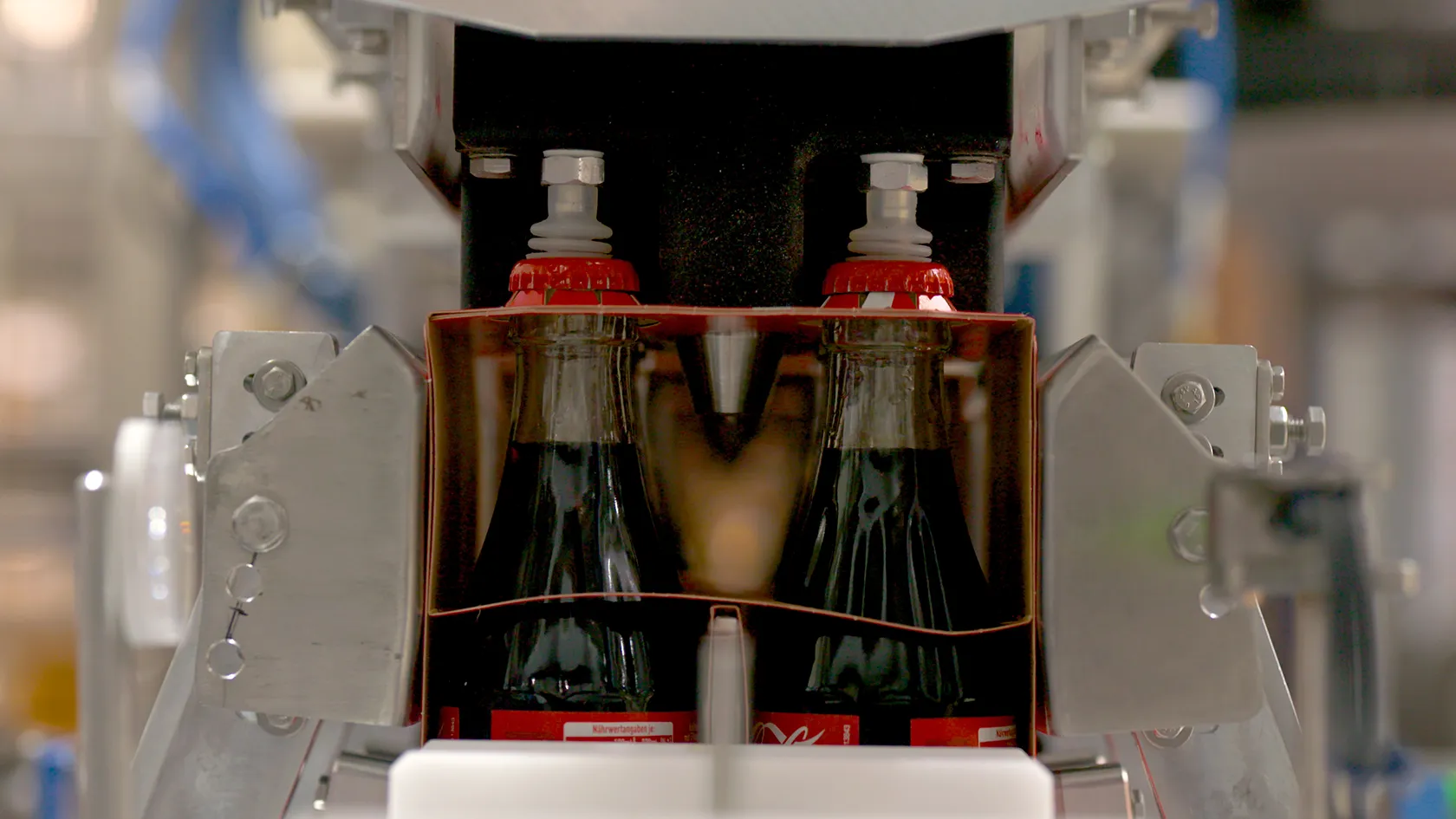

- Bottles are automatically placed from the crate into the cluster from above

- Unfolding of the clips and application to the bottles

- Automatic gluing of clips and clusters

- The finished packs are automatically lifted back into the crate.

- The filled crate is removed from the machine.

- 10 packs per minute

- Fully automatic

Fully automatic solution with scalability and modularity for large production volumes.

- Single-track feeding of the crates into the system

- WEHO® Cluster are folded on a parallel transport line

- Bottles are automatically placed from the crate into the cluster from above

- Empty crates are transported parallel to the transport line

- WEHO® Clip is unfolded and placed on the bottles

- The completed packs are automatically lifted back into the crate

- The filled crates are removed from the system

- At least 48 packs per minute

- Fully automatic

- Additional modules for quality control of the crates and automated output possible

- Extension to WEHOVario® with mixer module possible

- Freely scalable depending on volume

WEHOVario® automates the loading of bottle crates with mixed six-packs.

- Loading of mixed crates with up to 3 types of beverage in the Vario-cell

- Single-track feeding of the crates into the system

- WEHO® Clusters are folded on a parallel transport line

- Bottles are automatically placed from above into the cluster

- Empty crates are transported parallel to the transport line

- WEHO® Clip is unfolded and placed on the bottles

- The completed packs are automatically lifted back into the crate

- The filled crates are removed from the machine

- At least 48 packs per minute fully automatically

| Beverage bottles | up to 288 bottles/min. |

| Wrap-Around-cardboard | up to 48 packs/min. |

| Hot melt adhesive | |

This project involved the final assembly, packaging and palletizing of cans for the chemical industry.

Filled cans are fed to the system in a single row. At the end position, the assembly robot removes the cans and places them in the assembly unit. At the same time, caps are fed from a bunker and placed on the can, after which they are pressed on.

| Degree of customization | |

|---|---|

| Industry | , |

| Machine size | |

| Machine type | , , , , , , |

| Dimensions |

< 300 mm |

| Main function | , , |

| Performance | , , |

| Products | , , |