Processing and packaging line for dumpling dough

Processing and packaging line for dumpling dough

FRI1801

| Task | Depalletizing boxes, packaging, feeding, cartoning and palletizing tubular bags |

| Size | XL |

| Industry | Vegetables |

| Main function | Moving, packaging, others |

| Interfaces | |

| Degree of customization | One of a kind |

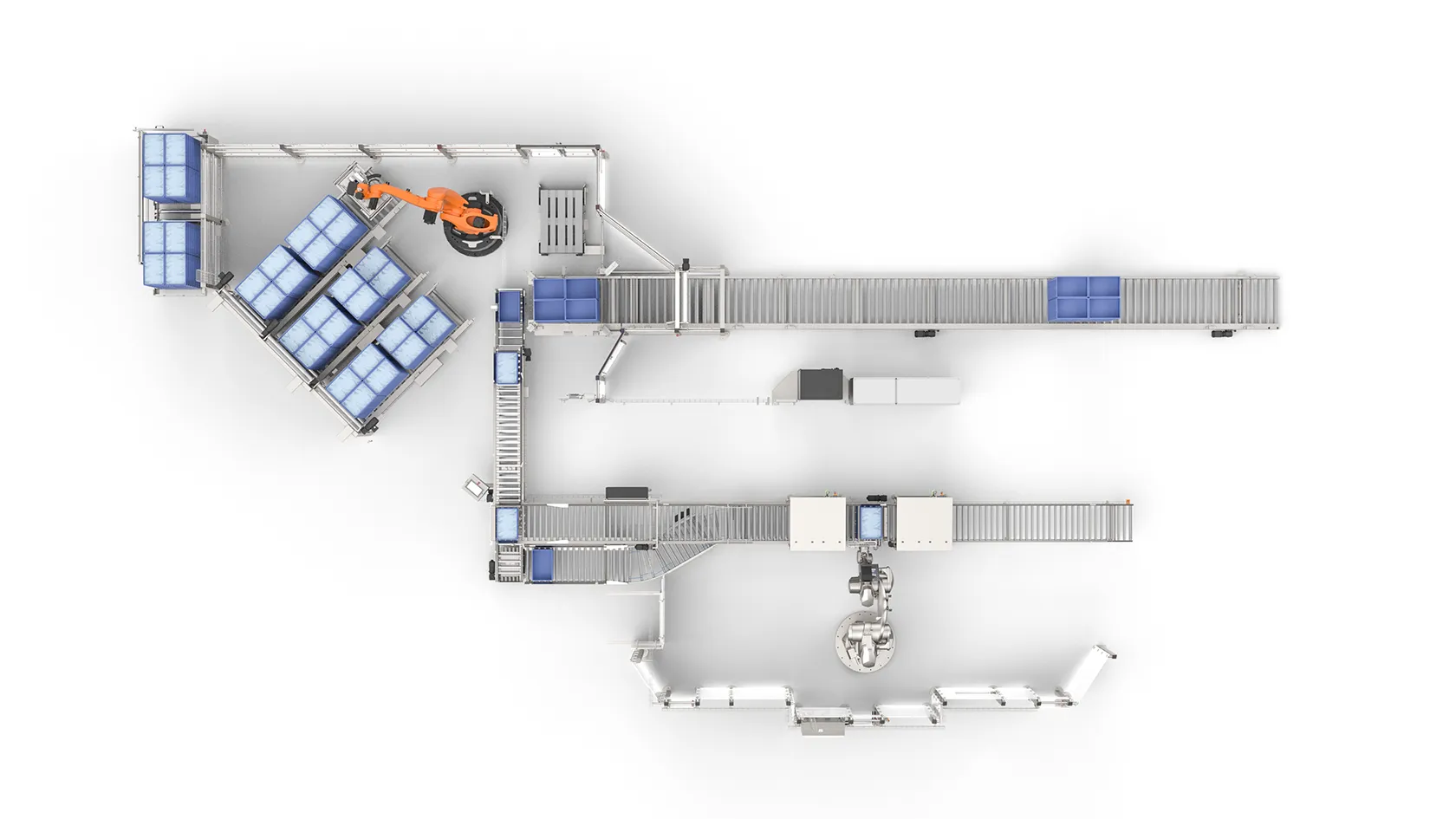

Depalletizing

Manual workplace

Emptying

Returning empty crates

Palletizing

Output

Pallet storage

Feed ``rolled dumplings``

Feed buckets and bags

Picking cell

Filling

Grouping

Palletizing

Feed empty pallets

Shuttle

Stretch wrappers

Output finished pallets

| Dumpling dough | up to 90 pieces/min. |

| Tubular bag | |

| E1 crates | 4 pieces/min. |

| Cardboard | 12 pieces/min. |

| Plastic pallet | |

| Challenges | Complete plant design Hygienic design |

Hier kommt ein kurzes Zitat des Kunden rein.

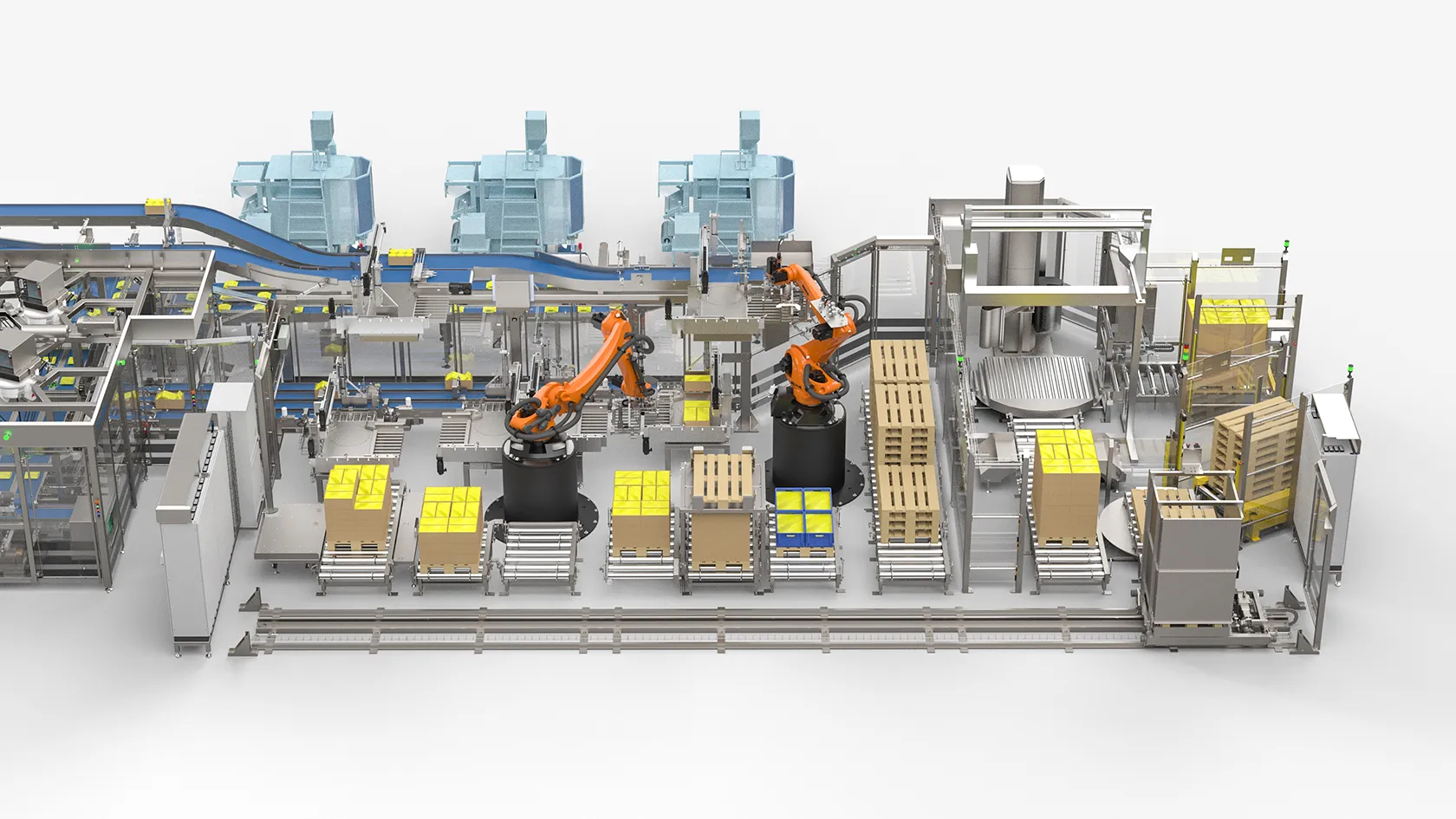

In this extensive project, a packaging line for dumpling dough was realized, from the supply of the potato pieces to the palletizing.

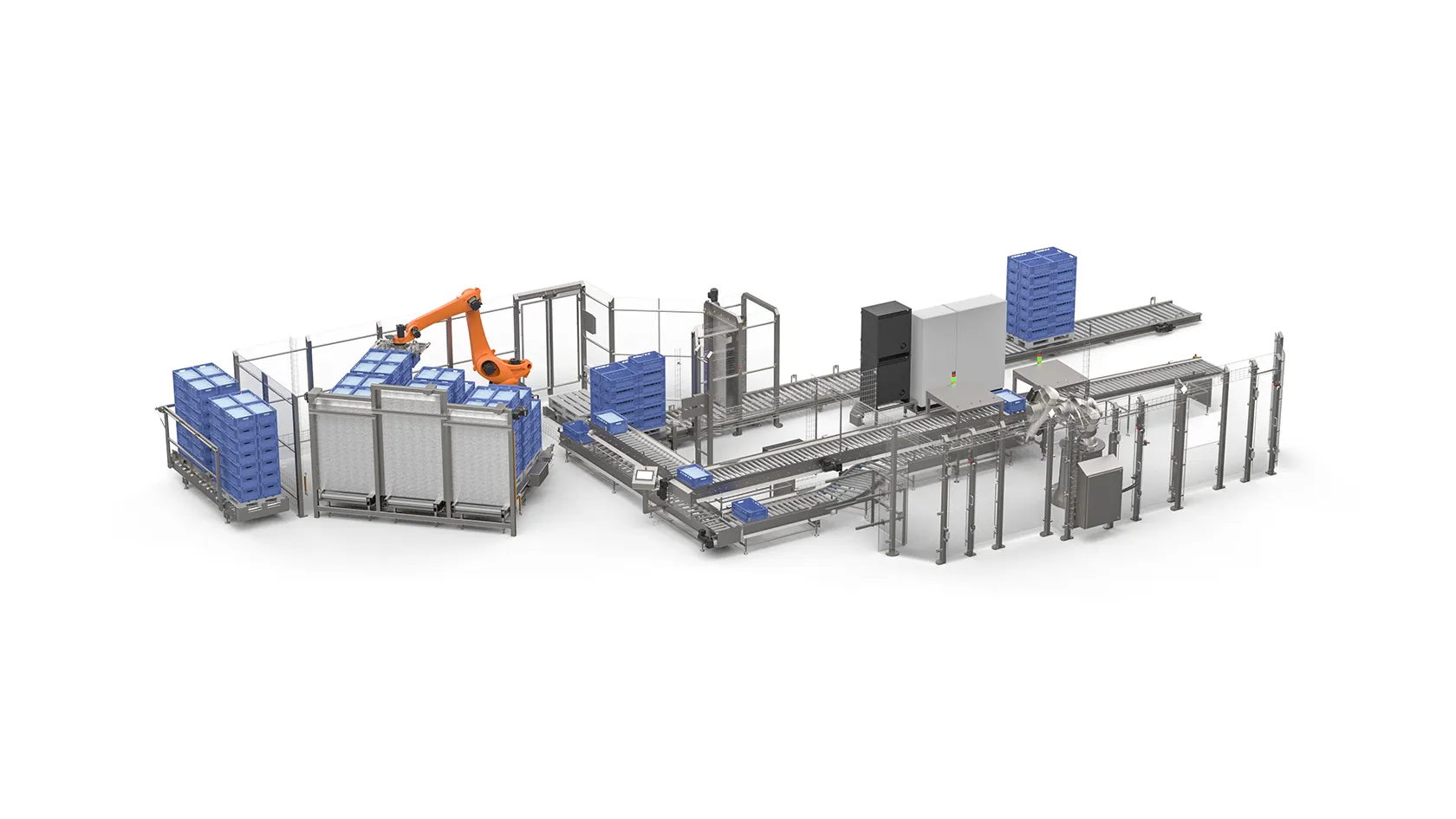

Product supply dumpling dough

The delivery of the potato pieces is carried out in K24 boxes on plastic pallets. These are distributed with a forklift truck on 3 roller conveyors. From there, a robot unloads the crates and sets them down on a roller conveyor that transports them to the emptying station. The emptying robot grabs the crates from the side and tips them over a grinding funnel. The emptied crates are transported back to the depalletizing unit on a lower roller conveyor, where the robot picks them up and stacks them on a pallet again.

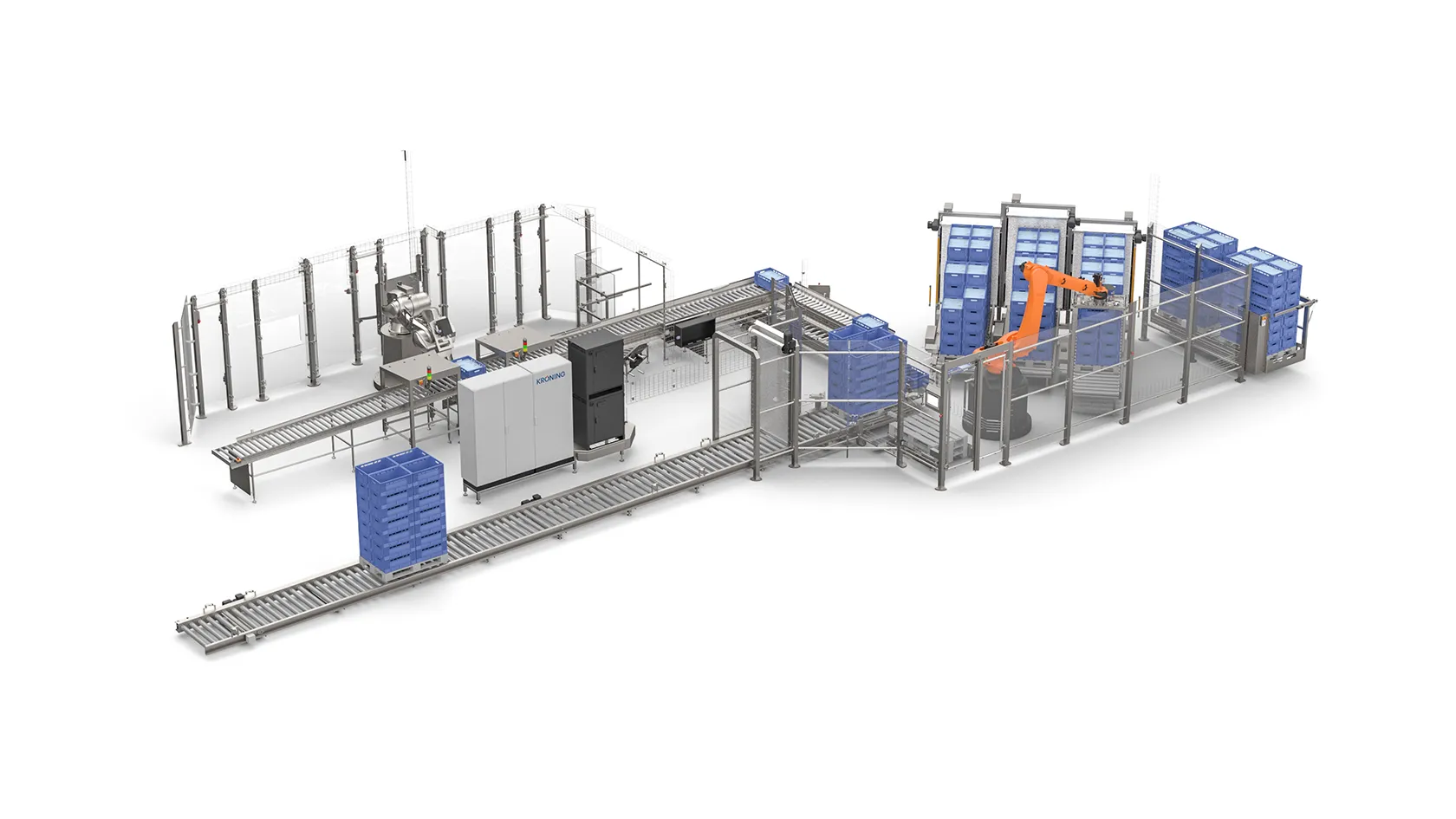

Incorporation of existing hardware and feeding to the case packer

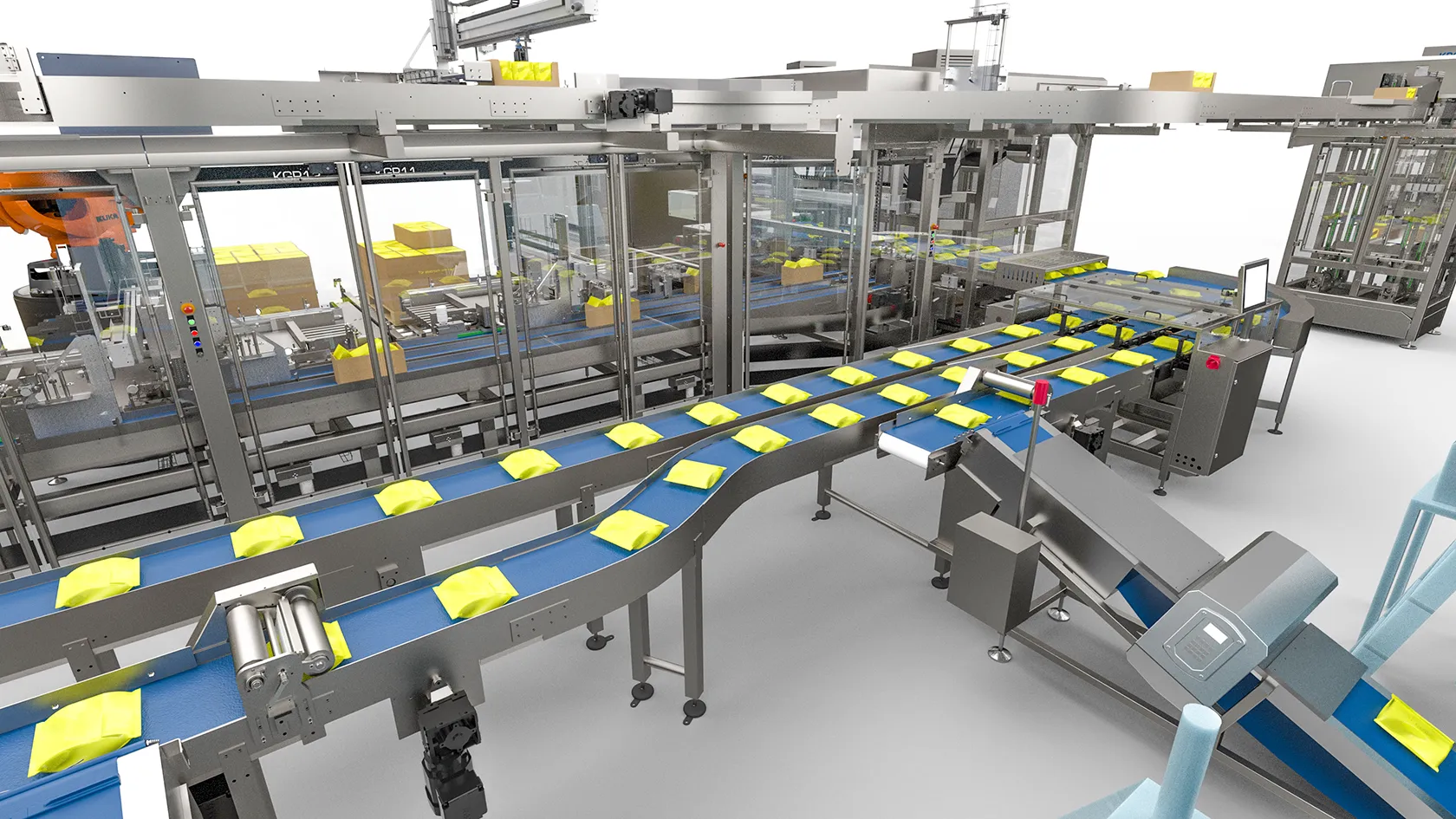

After the potato pieces have been processed into dumpling dough in the grinding hoppers, they are filled into bags in three existing form-fill-seal machines and fed to the case packer via conveyor belts. A metal check and a discharge are integrated here.

Case packer

The dumpling dough bags are fed into the picker cell on three conveyor belts, where they are placed in folding boxes by two delta robots. The boxes are conveyed from the box erector below the picker line to the filling position. Each robot fills four boxes, which are then conveyed to the palletizing station in a timed sequence on four conveyor belts.

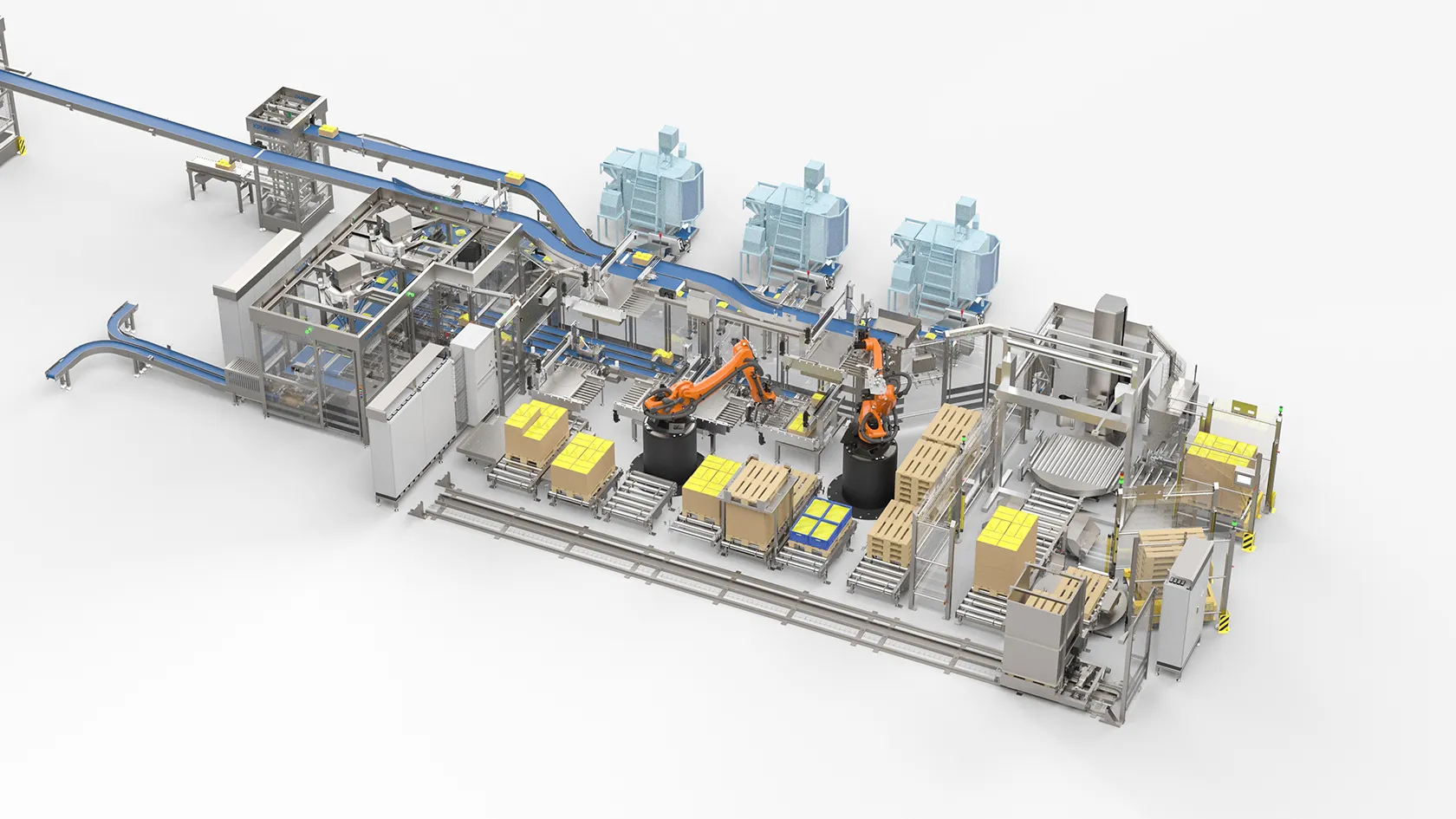

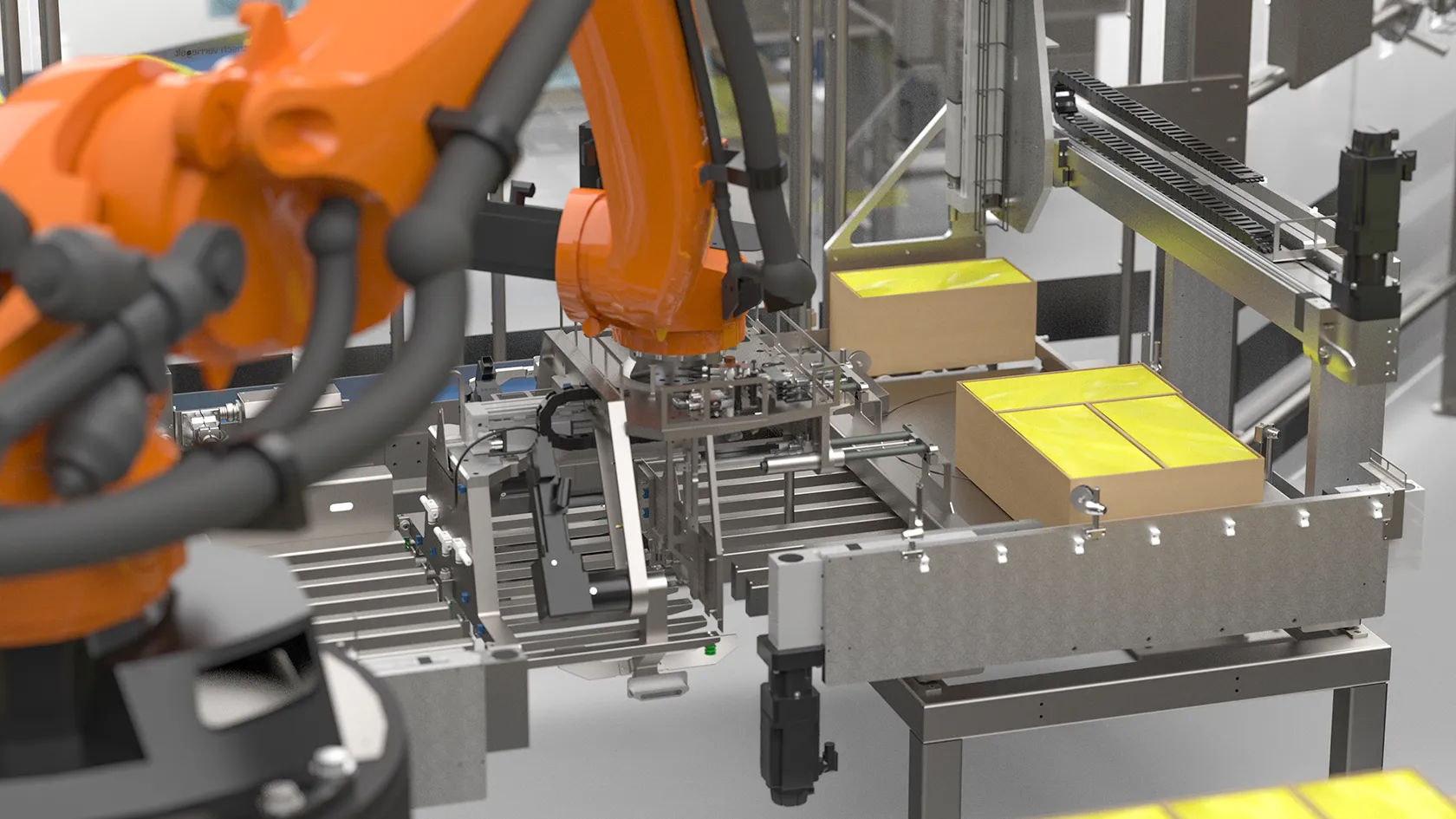

Palletizing

When the cartons arrive at one of the four palletizing stations, they are placed on a mesh table by means of a turning mechanism in such a way that the base area fits on a wooden pallet. A robot then moves under the table with a fork tool and lifts the cartons onto a pallet. When the pallet is full, it is transported on a roller conveyor to a wrapping machine and wrapped in film before being discharged and unloaded by a forklift truck.

| Degree of customization | |

|---|---|

| Industry | , |

| Machine size | |

| Machine type | , , , , , , , , , , , , , , |

| Main function | , , |

| Performance | , |

| Products | , , , , , , |