Packaging machine for bars

Packaging machine for bars

FRY1901

| Task | Transport, packaging and boxing of chocolate bars |

| Size | L |

| Industry | Chocolate |

| Main function | Moving, packaging, others |

| Interfaces | |

| Degree of customization | Standard |

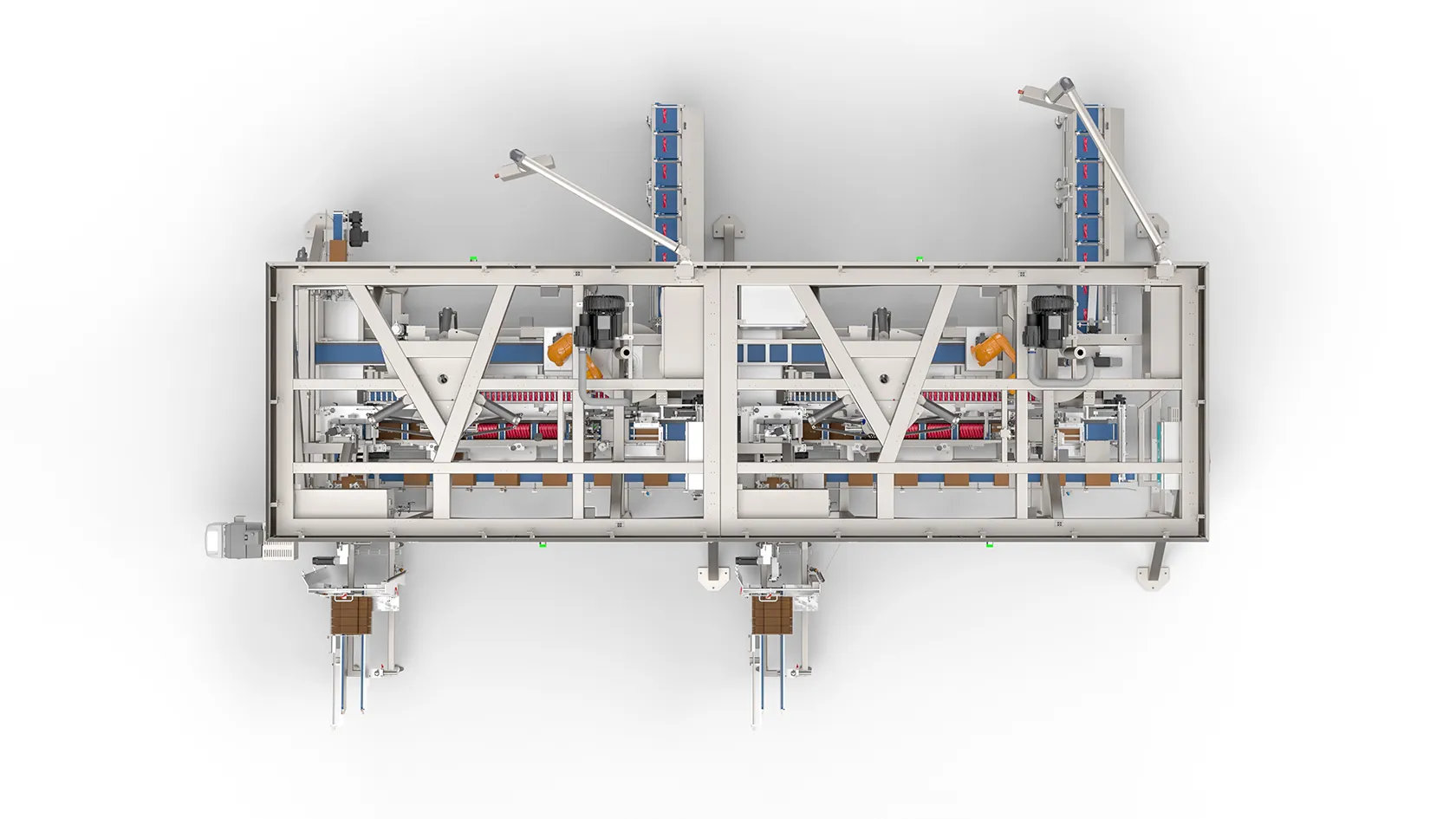

Feed bars

Transfer robot

Magazine cardboard

Synchronized chain boxes

Closure boxes

Output filled boxes

Reloading robot

| Chocolate bars | up to 450 pieces/min. |

| Carton with attached lid | up to 60 pieces/min. |

| Challenges | Set-up-free processing of 5, 7 and 10 bar groups |

Hier kommt ein kurzes Zitat des Kunden rein.

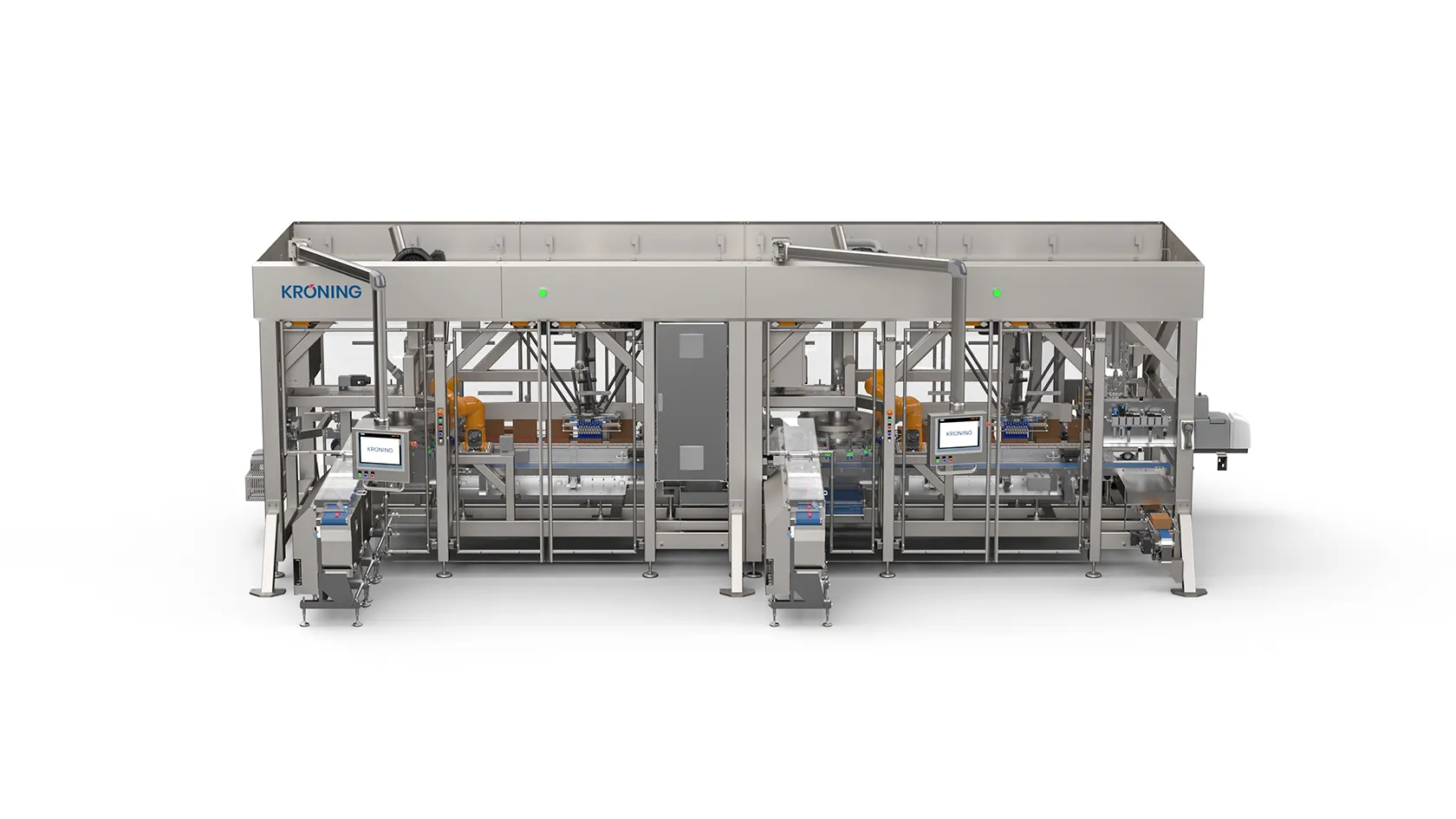

This project involved the feeding and cartoning of chocolate bars.

After the flow-wrapping machine, the bars are taken over on a belt cascade, weighed and detected. The cascade accelerates the individual bars so that they can be picked up by a downstream rotary converter.

This sets the bars down at 90° on the indexing conveyor of the robot cell. Here the robot transfer unit picks up the bars and places them either in folding boxes or in the feed for the multipacker. If the picker detects that one or more bars have not been properly picked up, the gaps are filled by a replenishing robot. This robot takes the bars from the conveyor belt behind the translator. When the boxes are full, they are transported further on the carton contact conveyor, the lid is glued and closed and the box is discharged from the system.

The picker line consists of two of these systems that can operate independently of each other. This means that one system can pack boxes while the other fills the multipacker.

| Degree of customization | |

|---|---|

| Industry | , |

| Machine size | |

| Machine type | , , , , , , , , |

| Main function | , , |

| Performance | , |

| Products | , , , , |