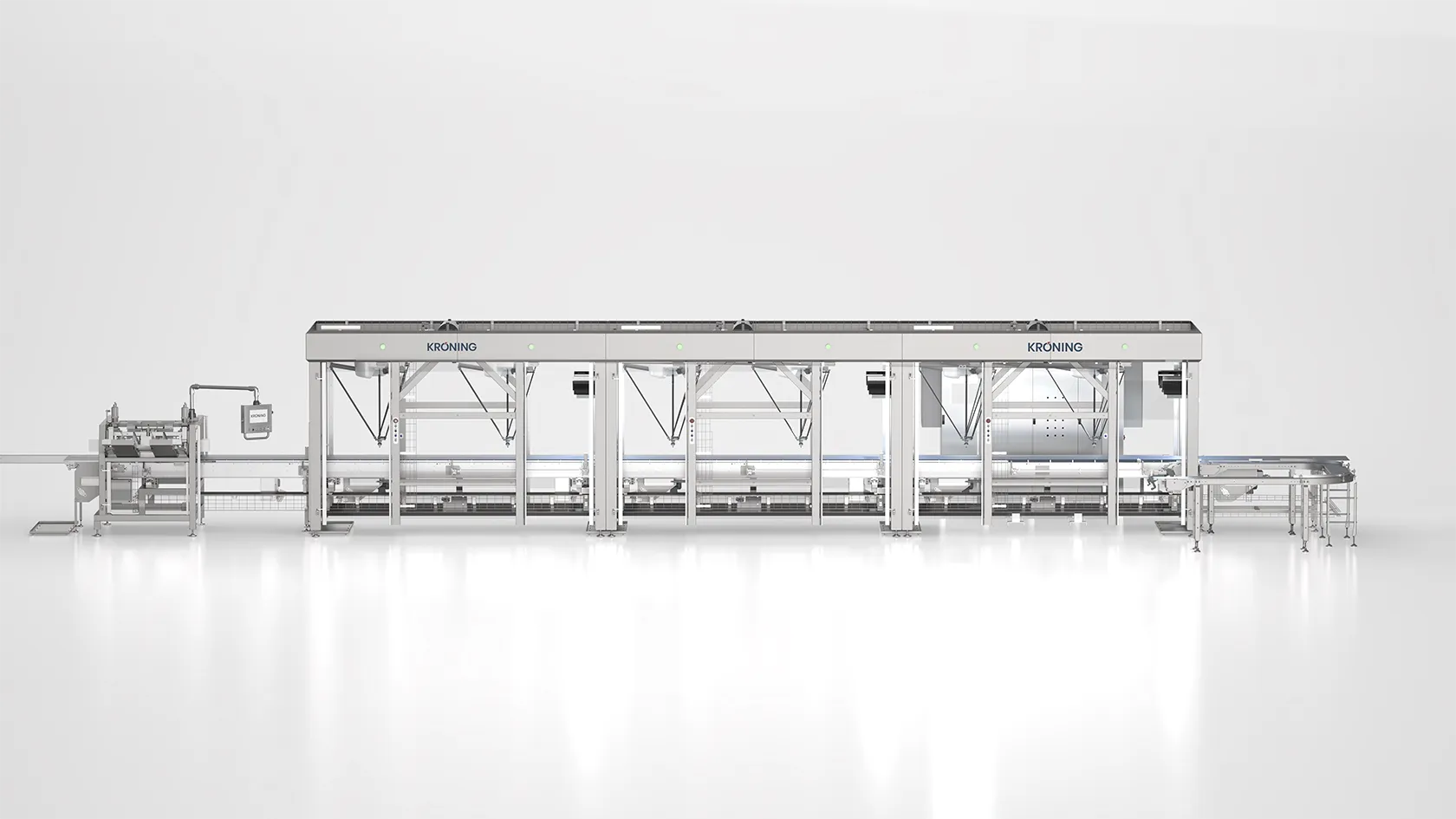

Packaging line for nougat articles

Packaging line for nougat articles

HSW1701

| Task | Transporting and feeding nougat items of various sizes to a form-fill-seal machine or inserting them into blisters |

| Size | L |

| Industry | Chocolate |

| Main function | Moving, packaging, others |

| Interface | Fuji-form-fill-seal machine |

| Degree of customization | Standard |

| Nougat articles | up to 700 pieces/min. |

| Blister | up to 40 pieces/min. |

| Challenges | Various product sizes, Blister and flow pack filling |

Hier kommt ein kurzes Zitat des Kunden rein.

This project involved the feeding and blister filling of nougat products.

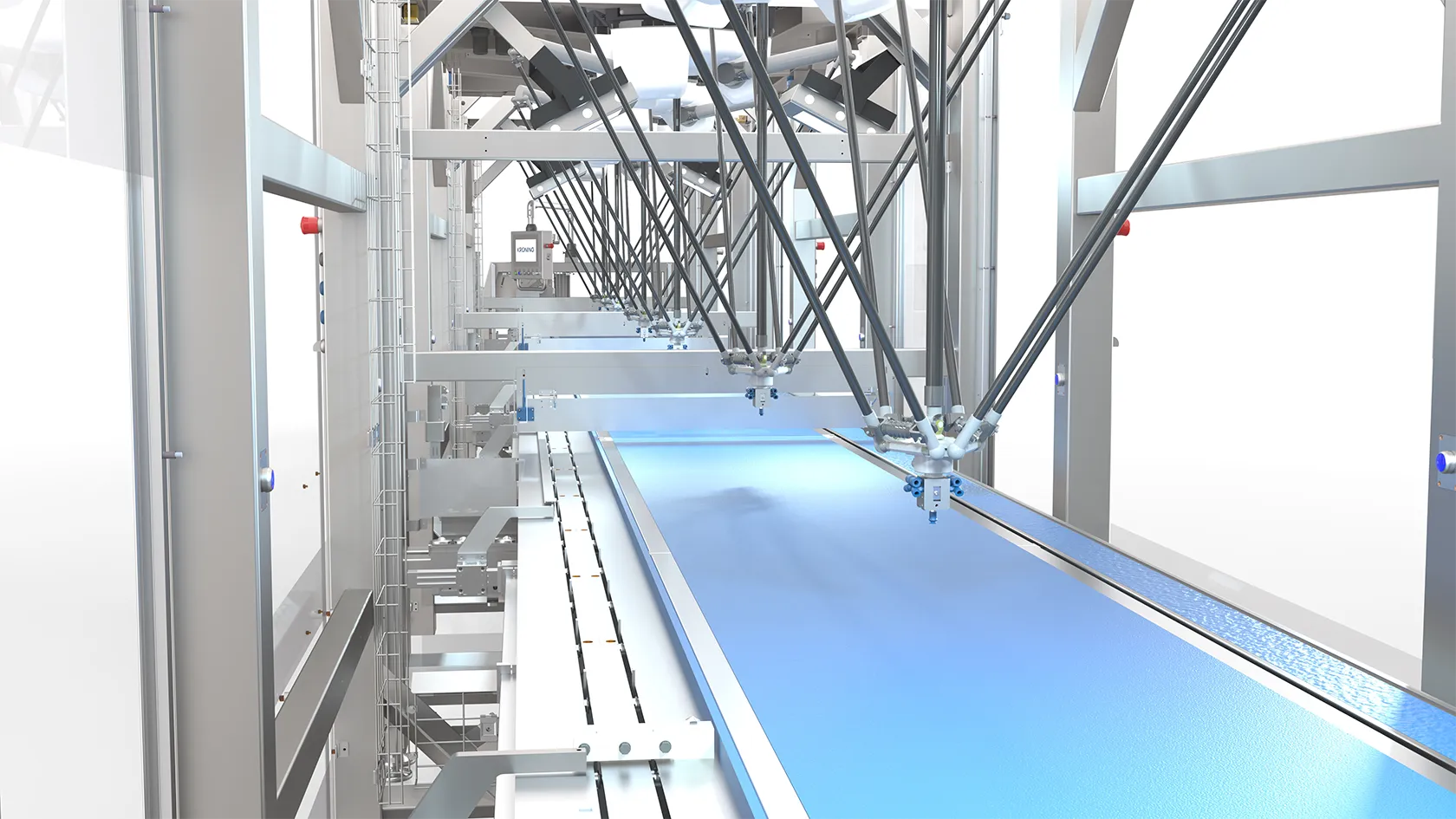

The nougat chocolates are fed into the system in rows on a conveyor belt and pass through three picker cells, each with two delta robots. Each cell has its own camera unit. The chocolates are picked individually by the robot and placed either on the flowpack belt or in blisters. The flowpack machine is fed in parallel in the same direction, while the blister chain is fed in parallel in the opposite direction. Once the nougat chocolates have passed the robot cells, they are centered and fed to the flow-wrapping machine. Articles that are not picked continue on the feed belt and are collected in boxes at the end.

At the end of the blister filling line, the blisters are taken from two magazines and placed on the chain belt. Light barriers at the picker cells recognize the blisters and start the filling process. When the blisters are full, they are fed to the packaging machine.

| Degree of customization | |

|---|---|

| Industry | , |

| Machine size | |

| Machine type | , , , , |

| Main function | , , |

| Performance | , |

| Products | , , |