Packaging line for advent calendars

Description

Packaging line for advent calendars

STR1801

| Task | Feeding and loading products into blisters and subsequent repackaging of the blisters |

| Size | L |

| Industry | Packaging service provider |

| Main function | Moving, Packaging, Others |

| Interfaces | |

| Degree of customization | One of a kind |

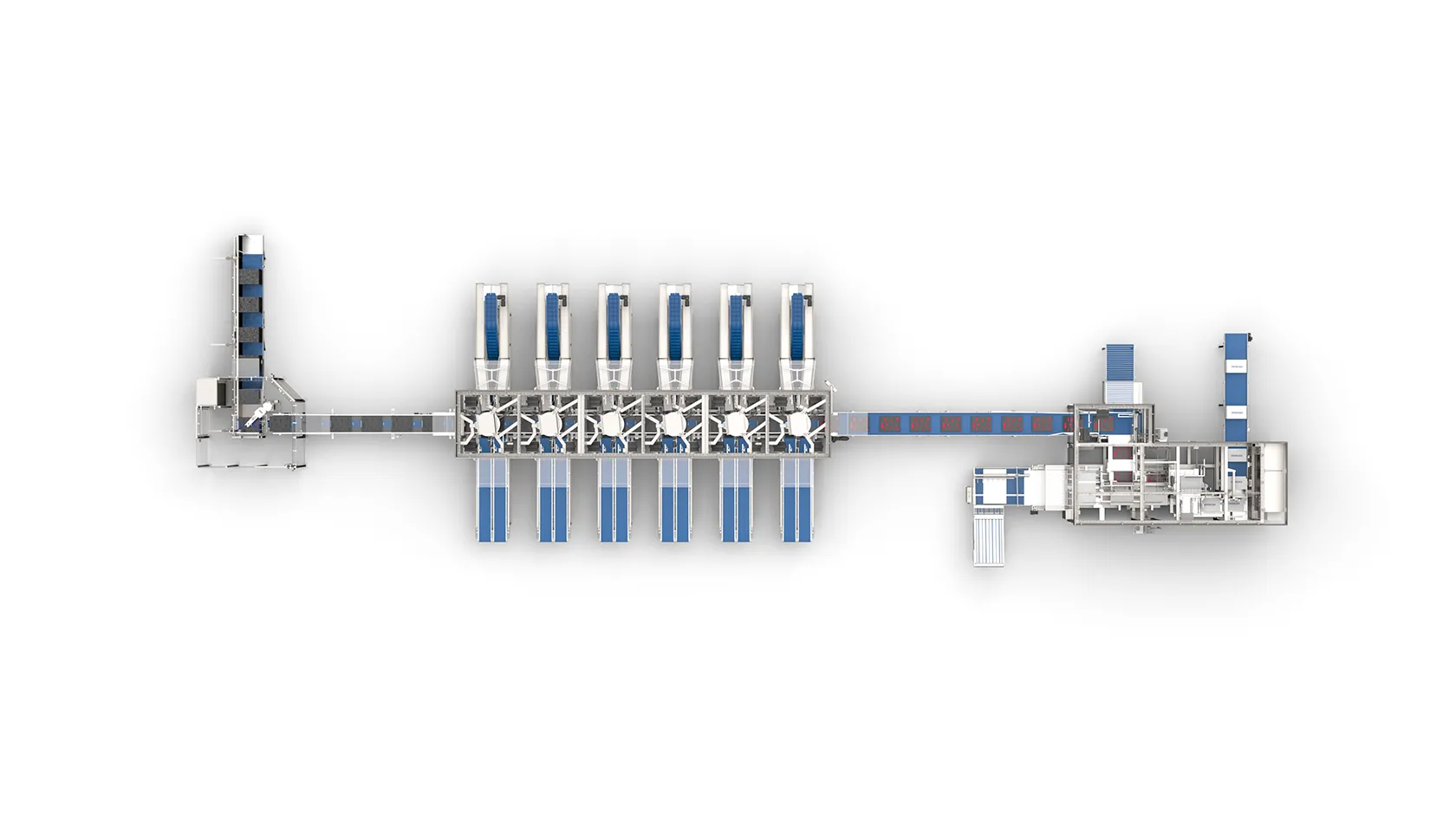

Loading blister stacks

Seperation blisters

Conveyor belt blister

Robot line assembly

Transfer band

Supply cardboard

Cardboard folder

Output finished products

| Cosmetics/beauty products | up to 500 units/min |

| Blister packs | up to 20 units/min |

| Cardboard | up to 20 units/min |

| Challenge | 24 different products |

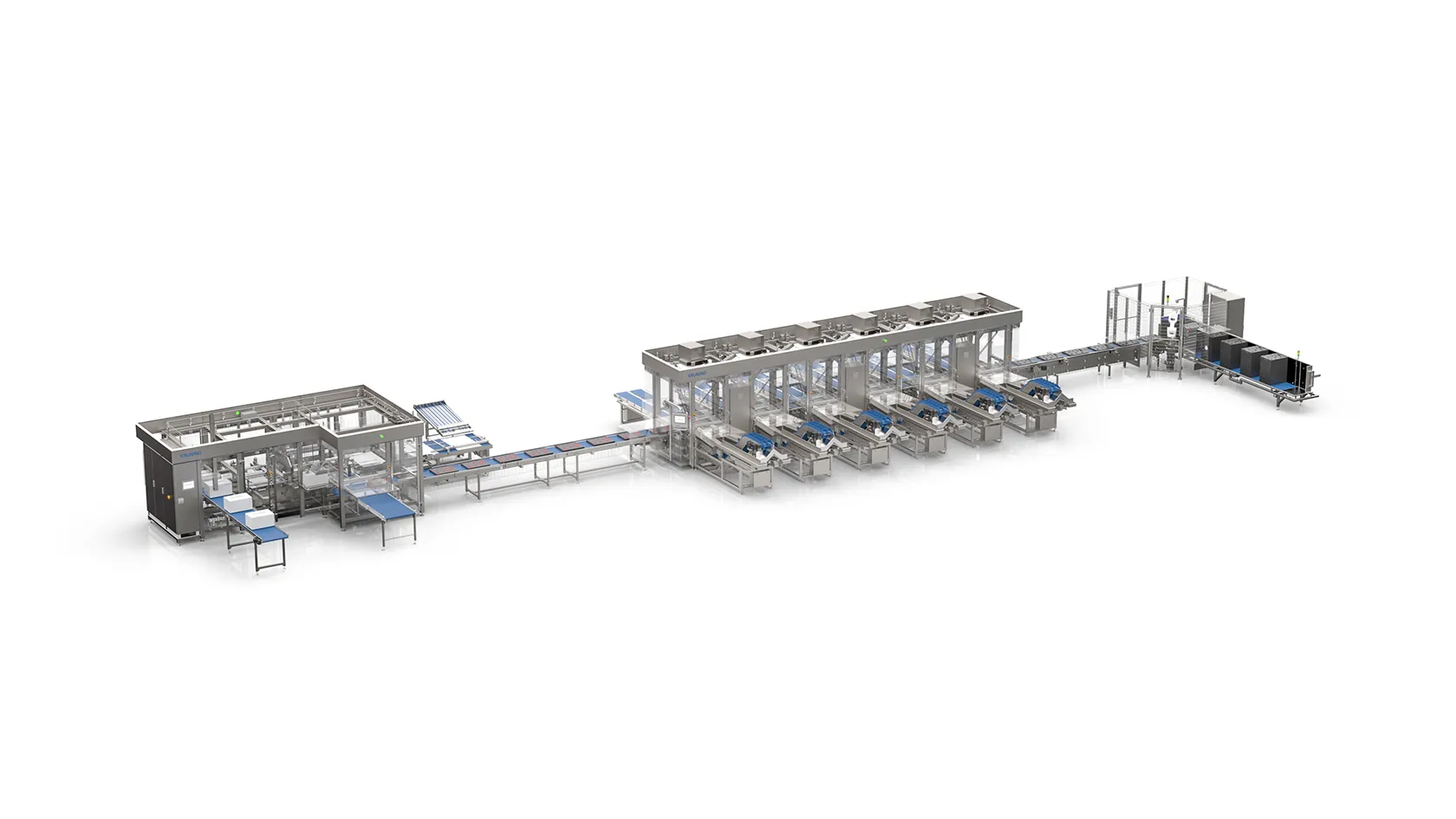

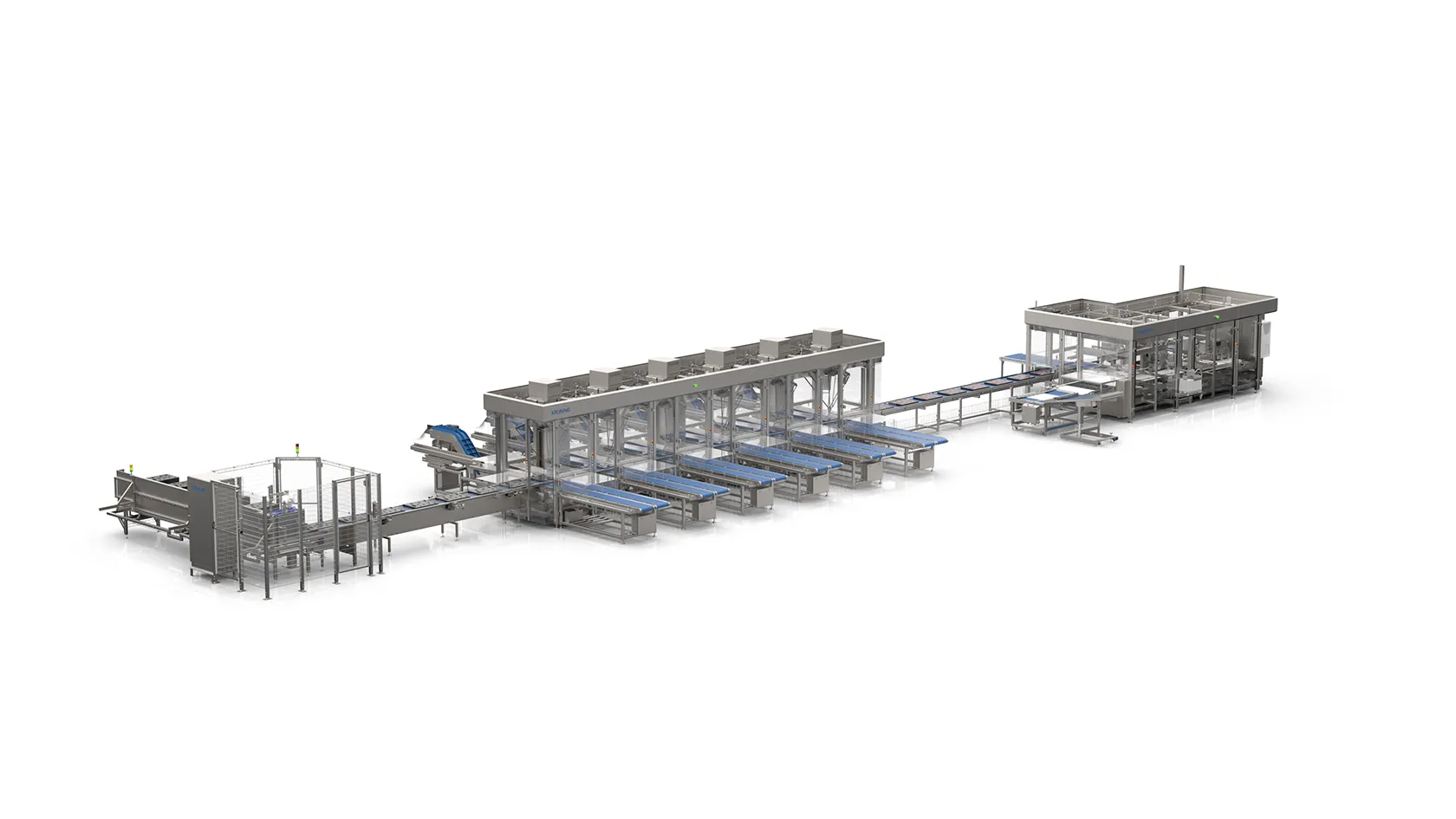

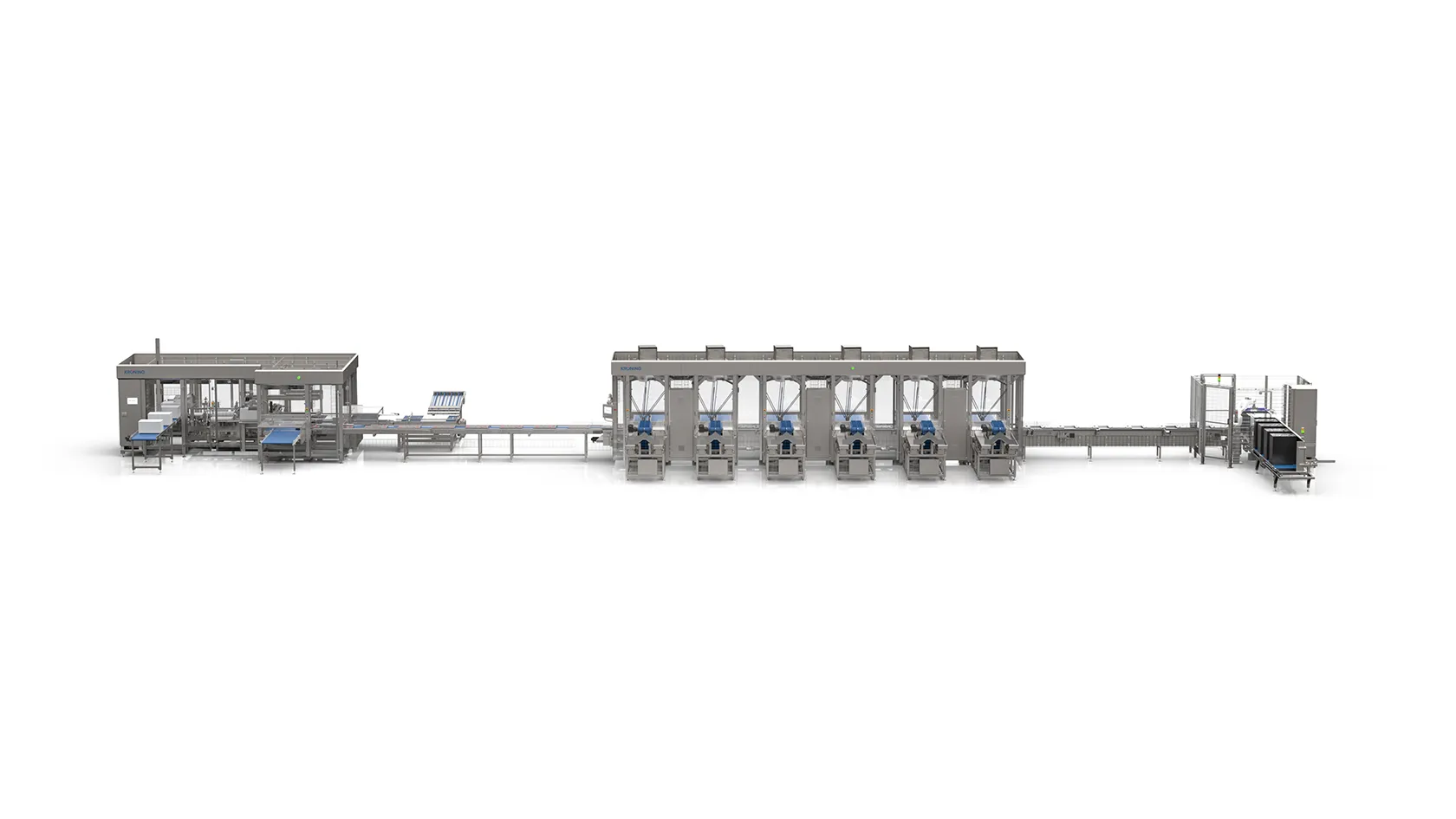

This project involved the feeding of blisters, the robotic insertion of products and the cartoning of the filled blisters.

Blisters are fed to the system in stacks and separated by a robot onto the infeed conveyor before being transported to the robotic line.

This consists of six consecutive cells in which a delta robot packs products into the cavities of the blisters from four infeed belts. Defective blisters can be manually re-fed on the subsequent transfer conveyor.

In the carton folder, the blisters are then cartoned, stacked and discharged.

Additional information

| Industry | , |

|---|---|

| Degree of customization | |

| Machine size | |

| Dimensions |

< 300 mm |

| Machine type | , , , , , , , |

| Performance | , |

| Main function | , , |

| Products | , , |