Mould changing system

Mould changing system

BLR1904

| Task | De-palletizing and palletizing plastic casting molds in the confectionery industry |

| Size | M |

| Industry | Chocolate |

| Main function | Moving, packaging, others |

| Interfaces | Bühler |

| Degree of customization | Standard |

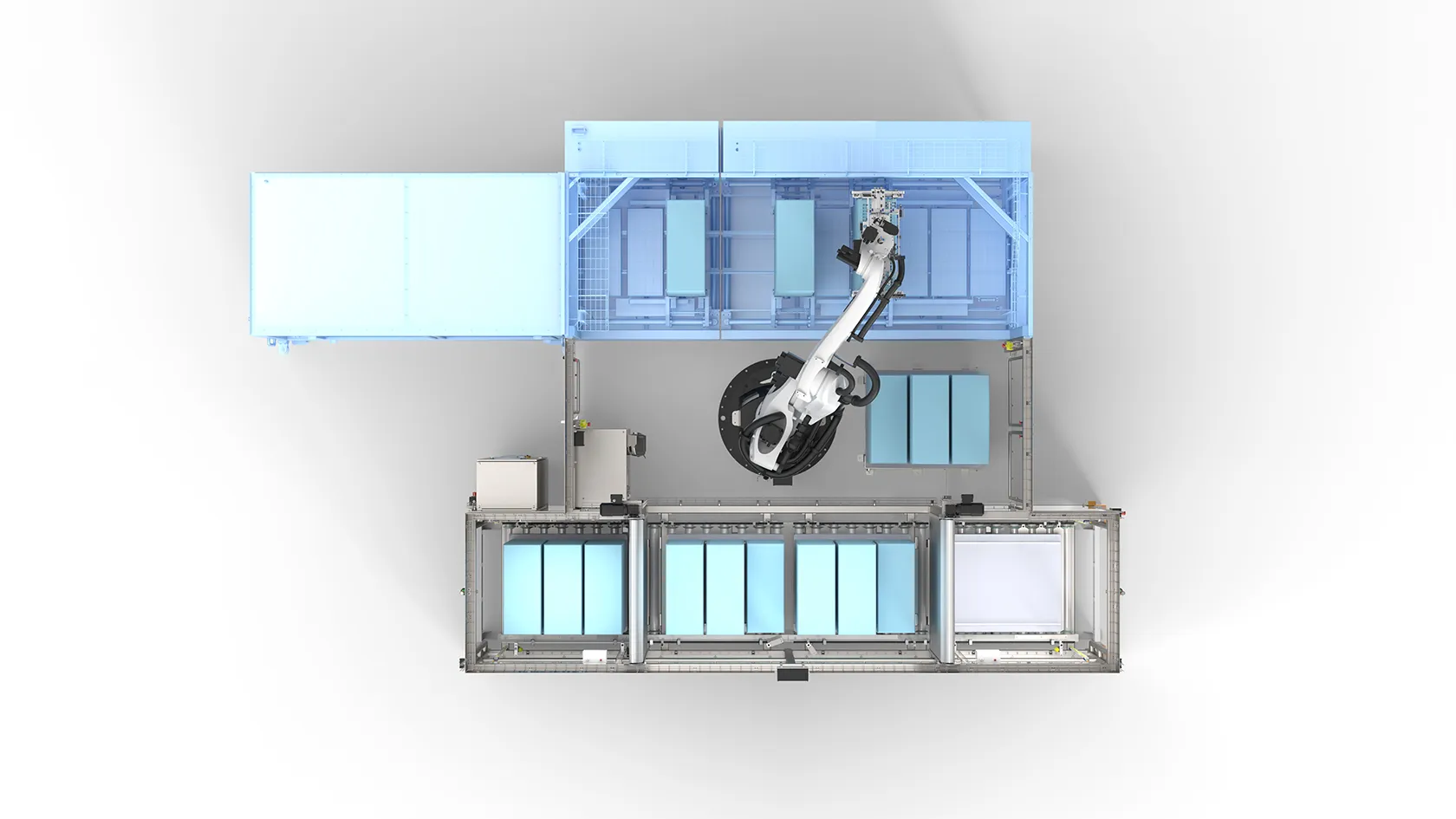

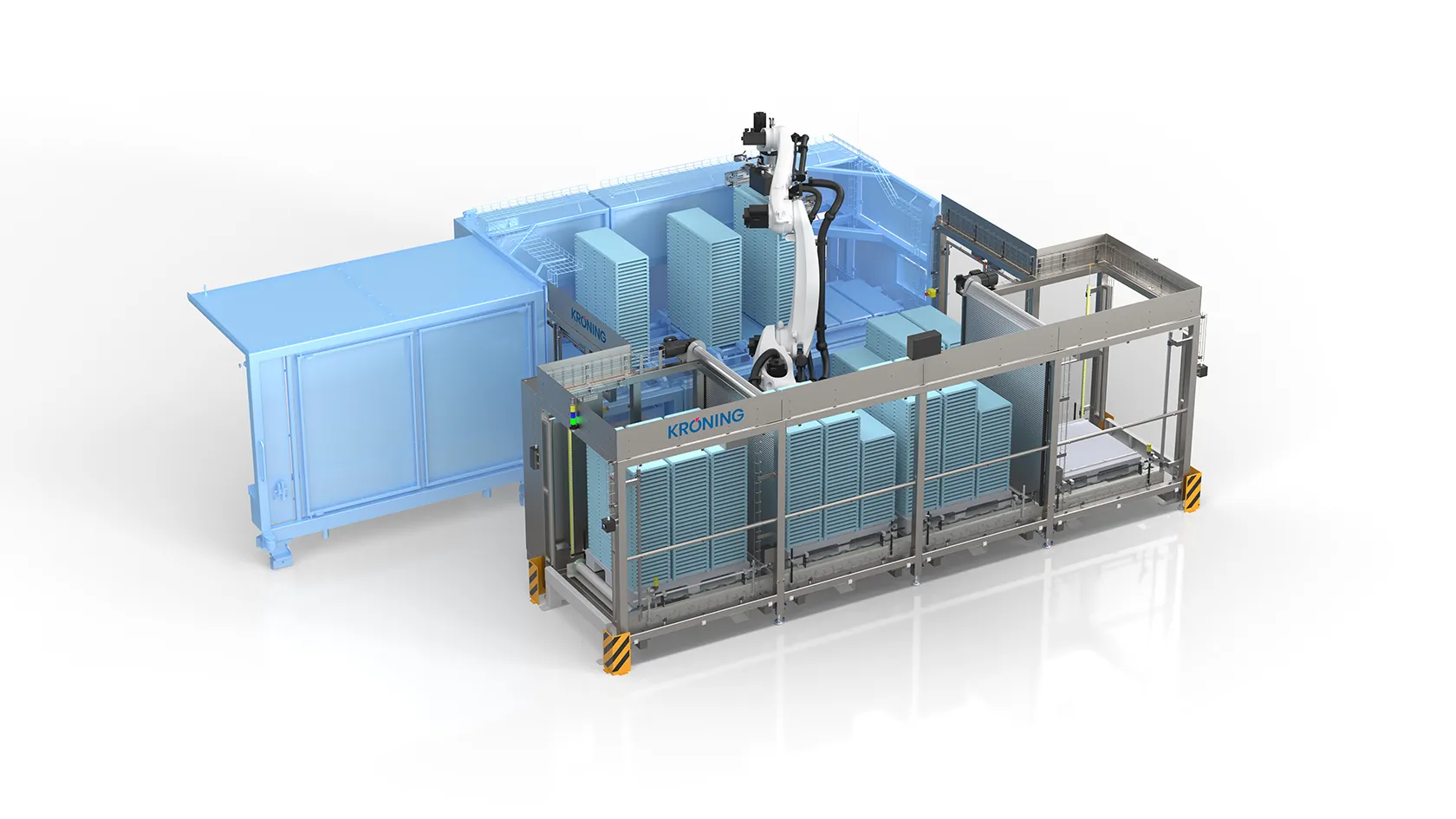

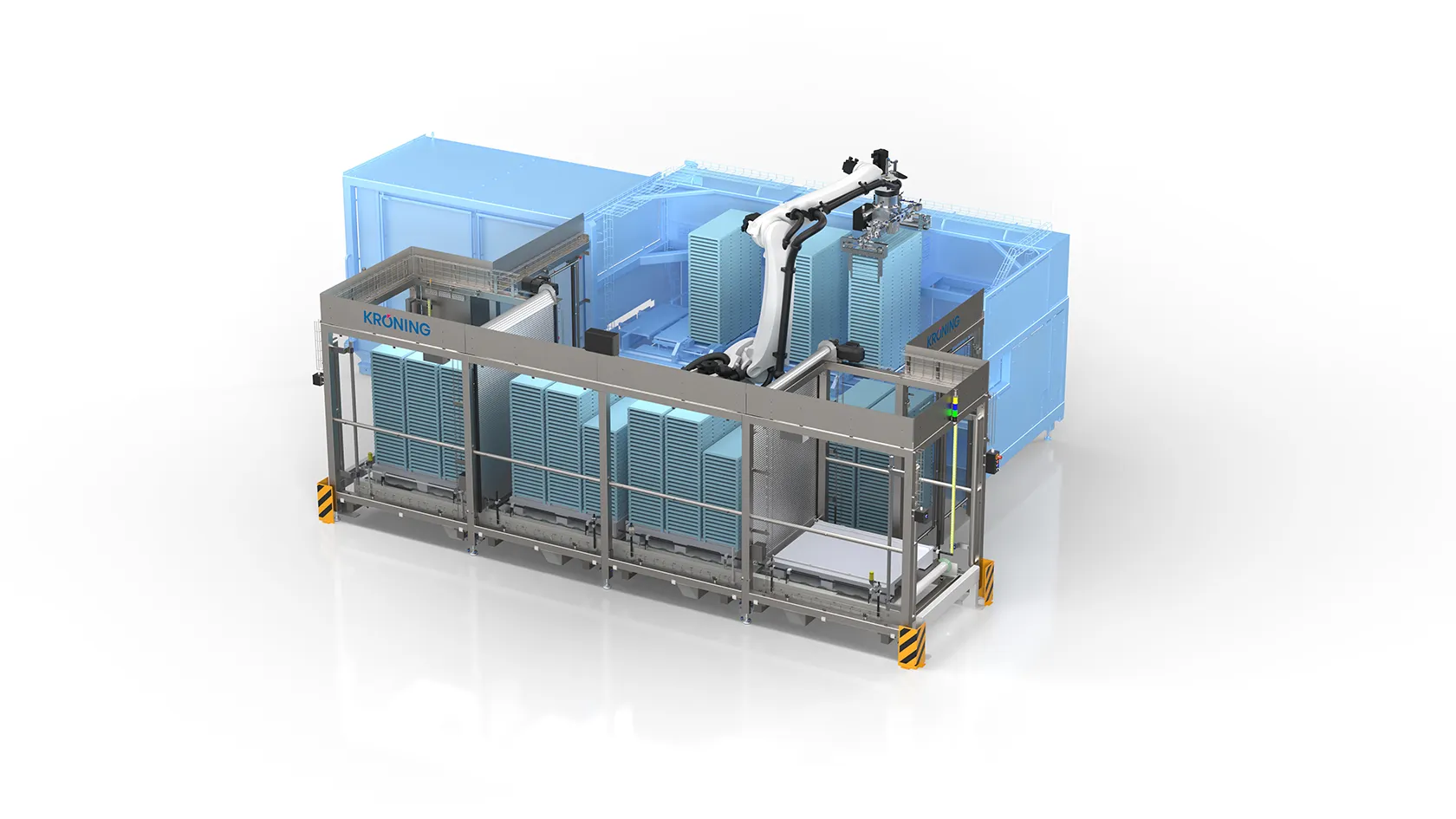

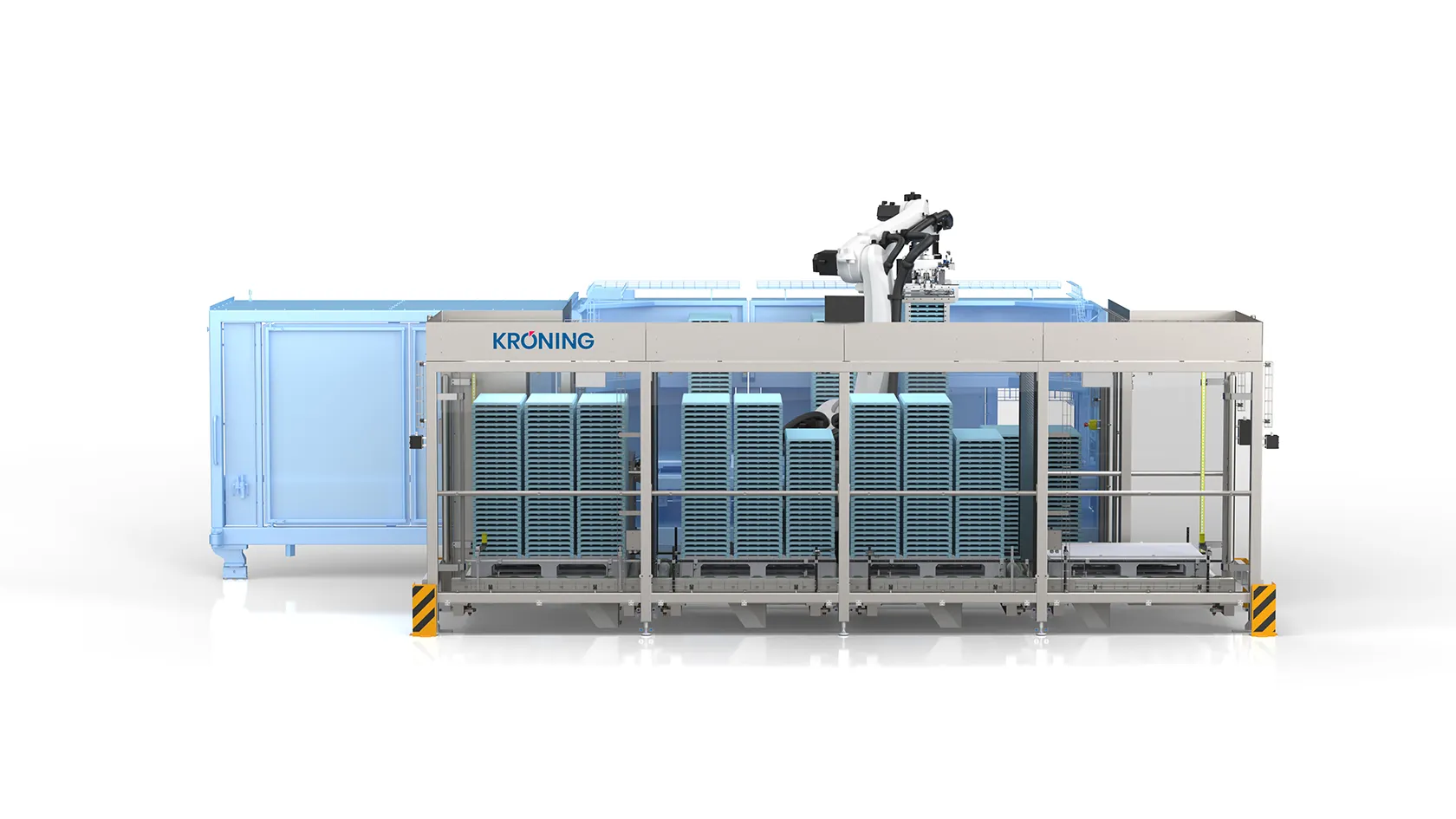

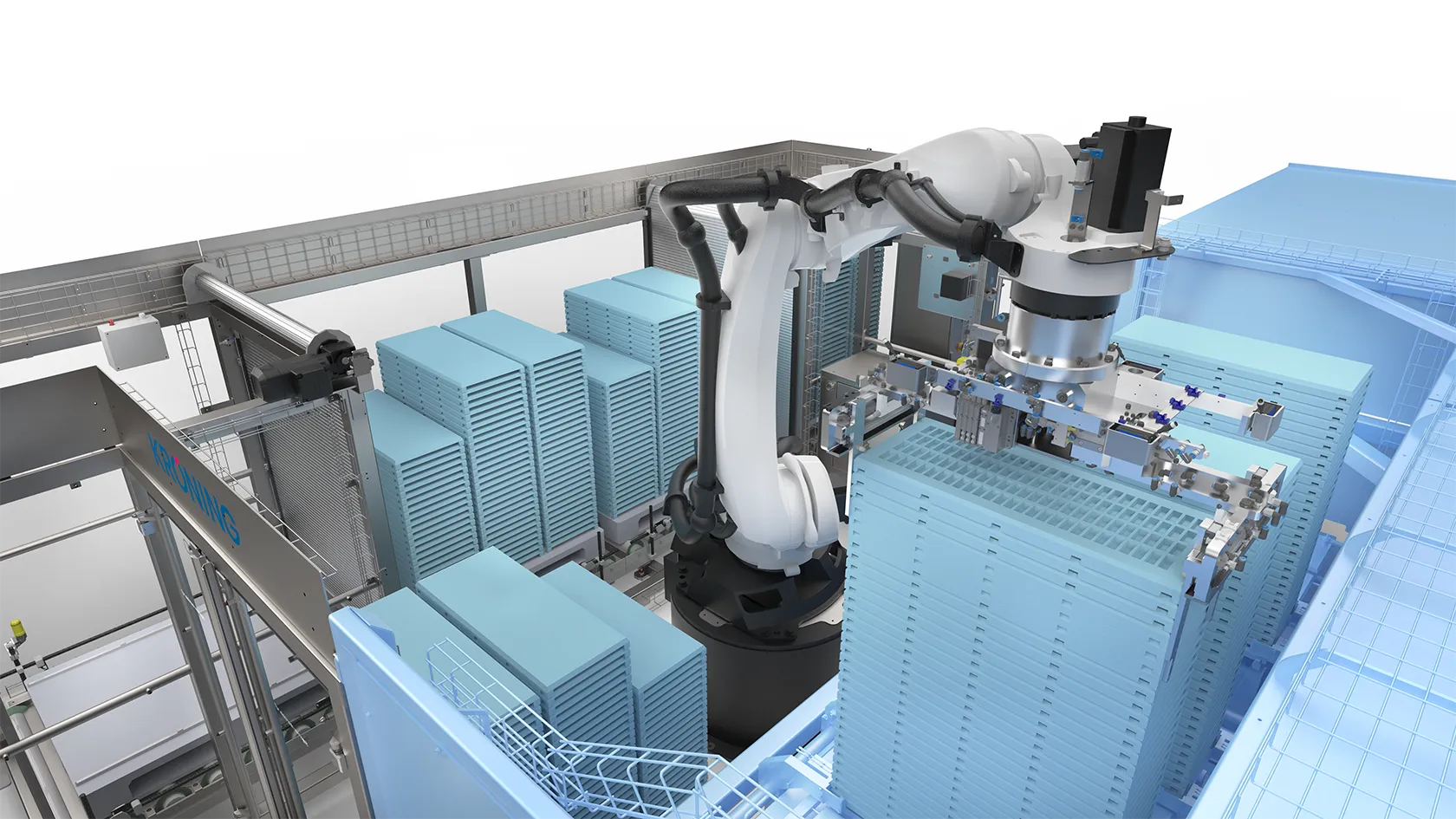

This project involved the realization of an automated mold-changing system. The system was designed to handle three scenarios: the introduction of new molds prior to production, intermediate storage during production, and the removal of all molds after production.

Before production, full pallets are fed into the change cell by forklift. They travel on a roller conveyor to their unloading position and are stacked by the robot in stacks at the input position in front of the casting machine. The empty pallets are output on the opposite side.

During production the robot picks up excess plates and stores them in a buffer position until space becomes available at the input position.

After production the empty pallets are fed into the system and scenario 1 is played backwards.

In all three programs, contaminated or damaged molds are ejected to a separate position and can be removed.

Feeding

Feeding

Output

Casting machine BÜHLER

| Mould (plastic) | 15 pieces/min. |

| Pallet (plastic) |

|

This project involved the realization of an automated mold-changing system. The system was designed to handle three scenarios: the introduction of new molds prior to production, intermediate storage during production, and the removal of all molds after production.

Before production, full pallets are fed into the change cell by forklift. They travel on a roller conveyor to their unloading position and are stacked by the robot in stacks at the input position in front of the casting machine. The empty pallets are output on the opposite side.

During production the robot picks up excess plates and stores them in a buffer position until space becomes available at the input position.

After production the empty pallets are fed into the system and scenario 1 is played backwards.

In all three programs, contaminated or damaged molds are ejected to a separate position and can be removed.

| Degree of customization | |

|---|---|

| Industry | , |

| Machine size | |

| Machine type | , , , |

| Main function | , , |

| Performance | |

| Products | , |