Egg tray handling

Description

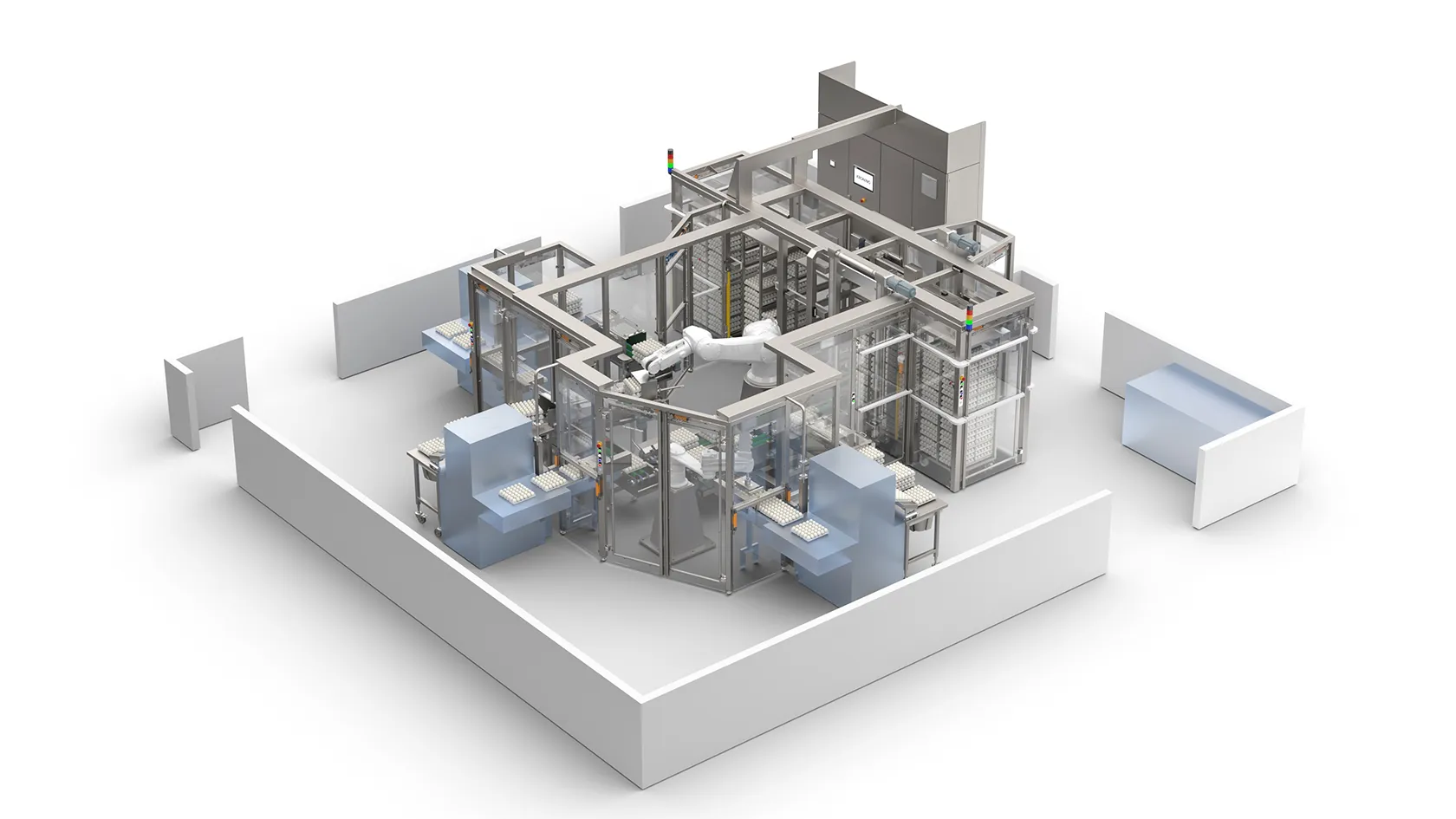

Egg tray handling

GSK2203

| Task | Automatic trolley-based transportation of egg trays to and from an egg sorter |

| Size | L |

| Industry | Pharmacy |

| Main function | Moving |

| Interfaces | |

| Degree of customization | Standard |

Feeding trolleys

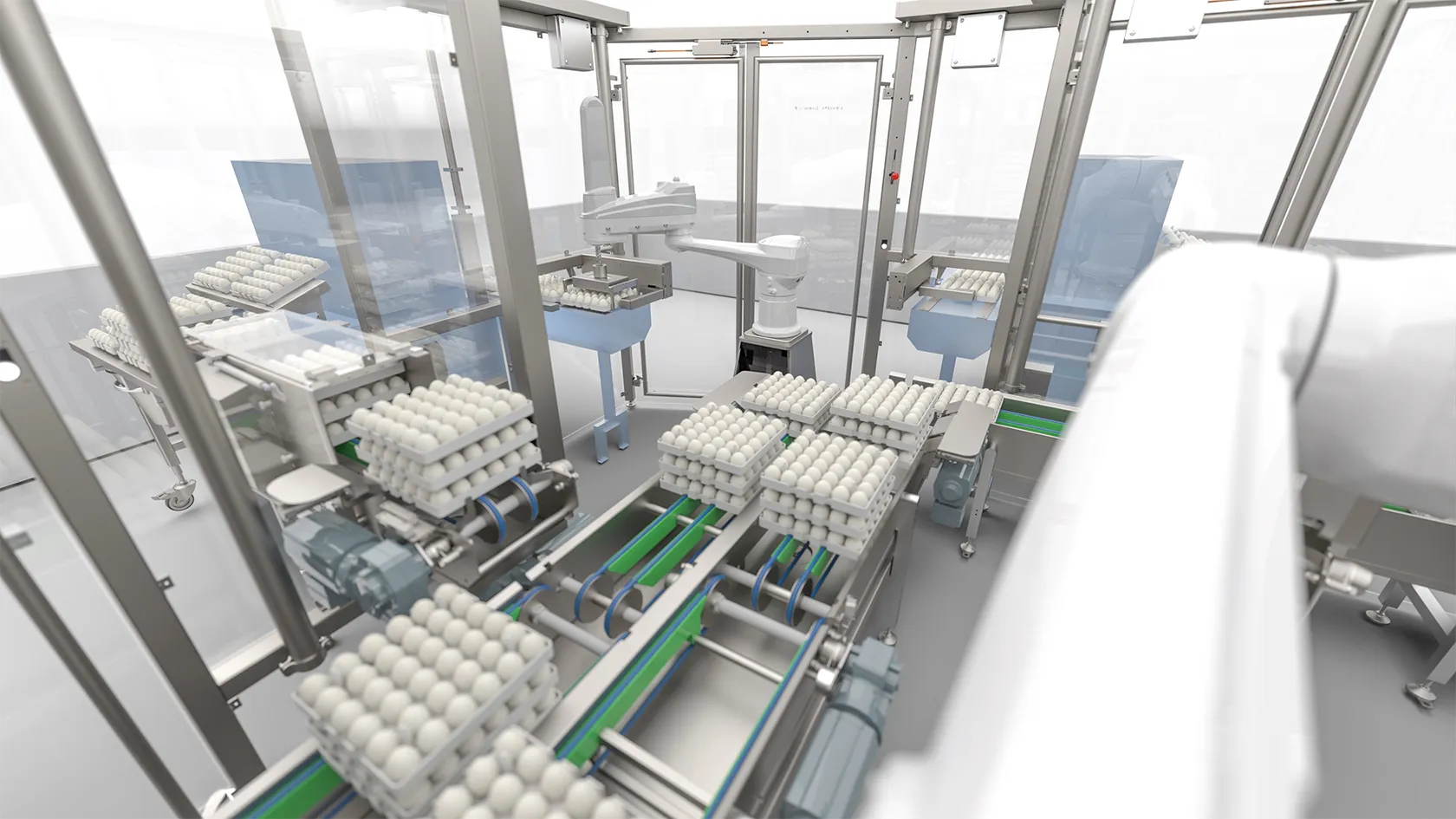

Feeding egg trays

Sight machine 1

Sight machine 2

Sight machine 3

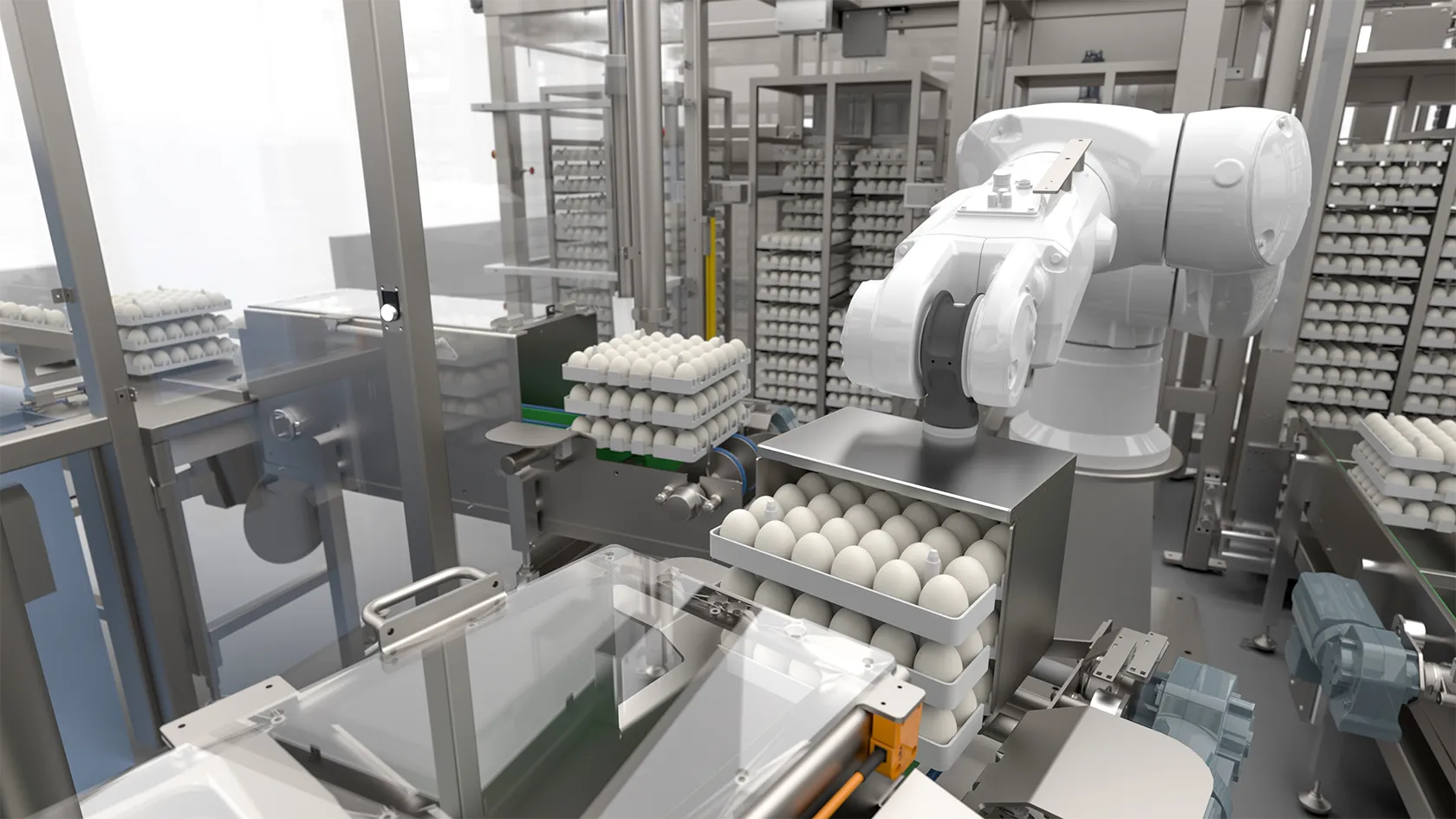

Distribution robot

Destacking and distributing racks to the sorting machines

Reverse-feed robot

Returning the stacked racks to the empty trolley

Output tested trolleys

| Egg trays | up to 21 pieces/min. |

| Trolley | up to 15 pieces/hour |

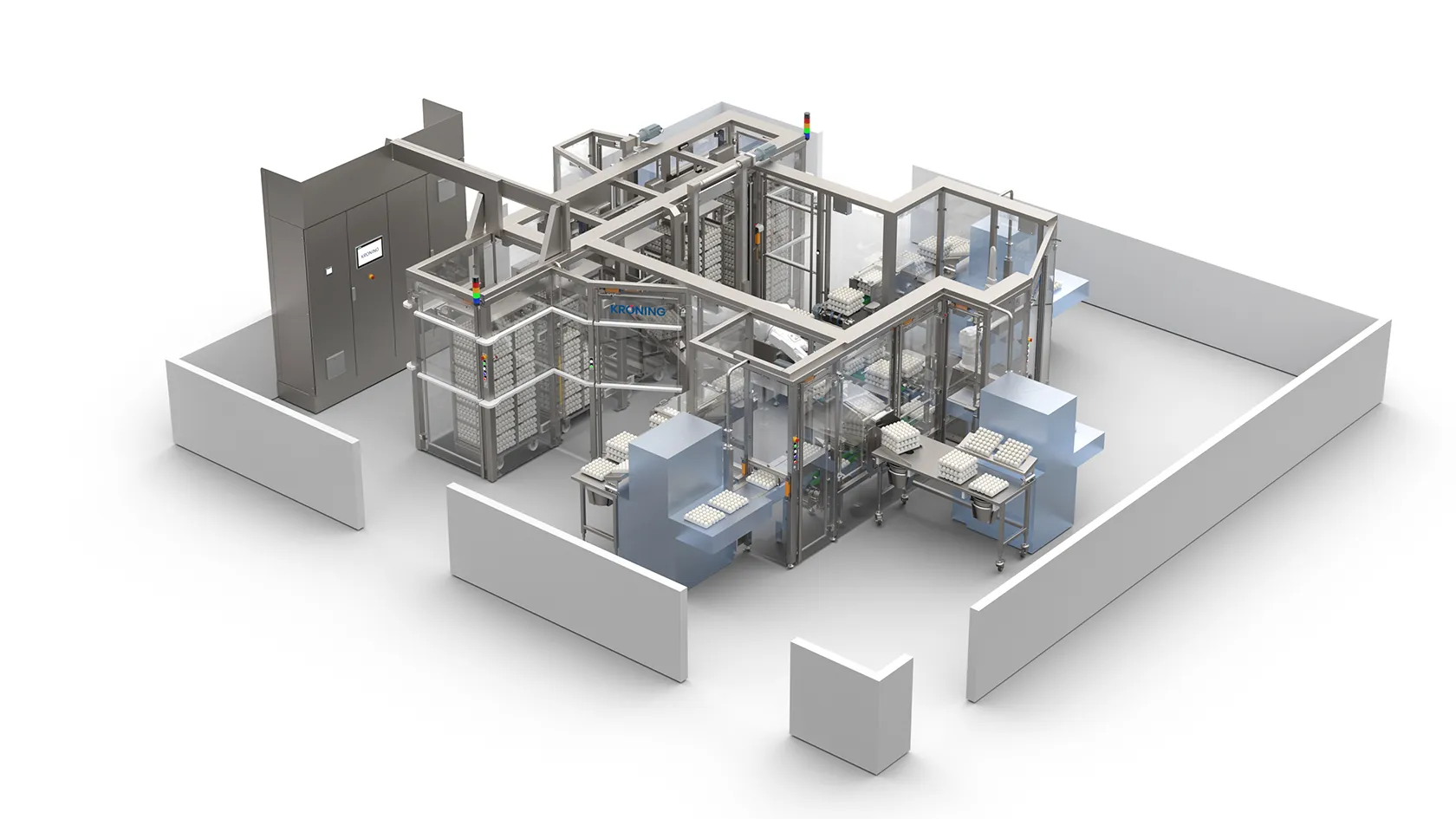

This project involved the realization of a horde handling system for hatching eggs for the pharmaceutical industry.

Hatching eggs are fed into the system in horde stacks using indoor trolleys. The hordes are then unloaded and fed to a distribution robot that assigns one horde each to one of three sifting machines (customer stock).

After the inspection, the racks are stacked again at a manual workstation and pushed into a feed shaft. The stacking robot removes them from the end position and pushes them back into an empty indoor trolley.

At the end of the line, the fully loaded trolleys with inspected hatching eggs can be removed.

Additional information

| Degree of customization | |

|---|---|

| Industry | , |

| Machine size | |

| Machine type | , , |

| Main function | |

| Performance | , |

| Products | , |