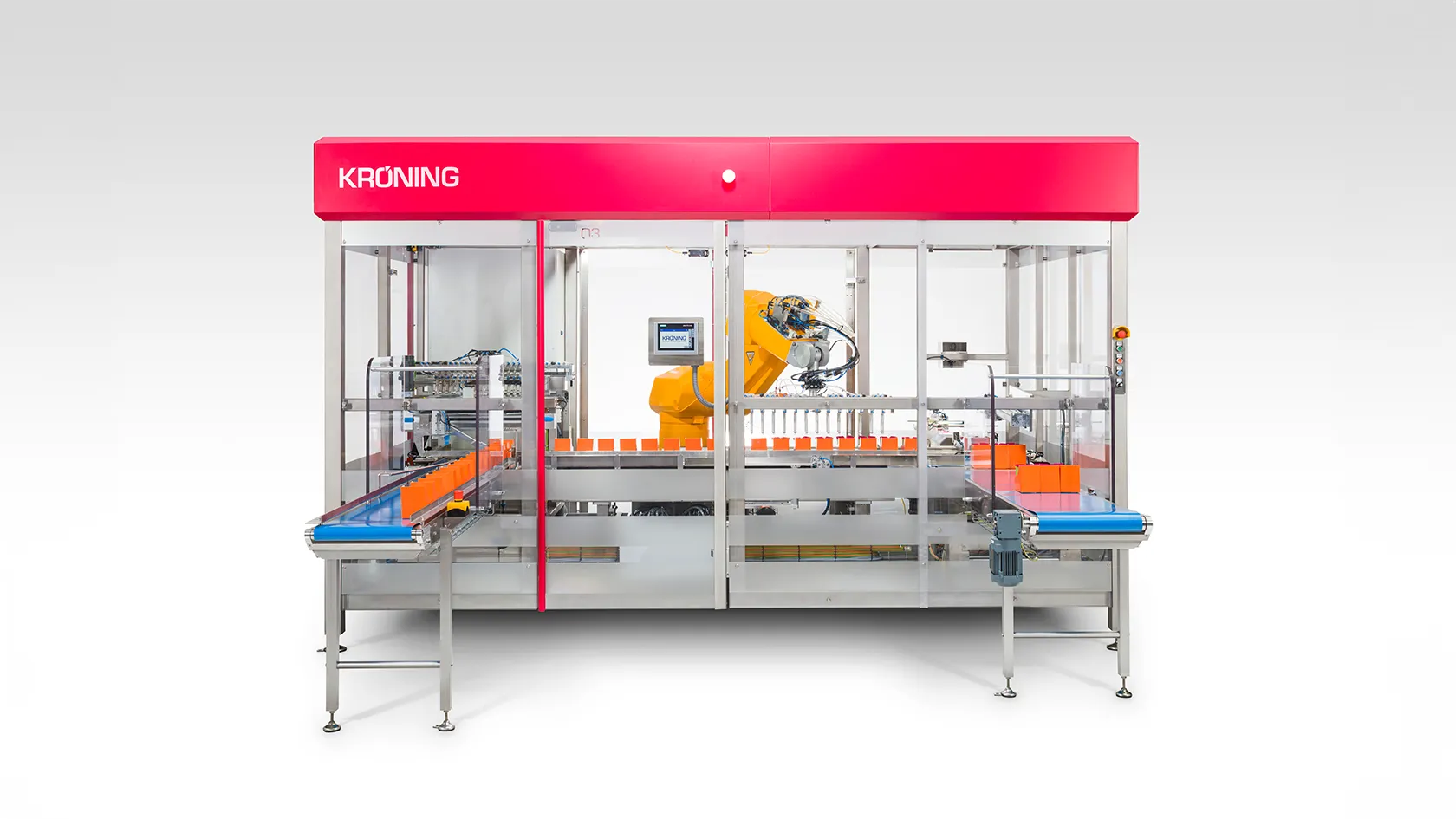

Cartoner for fruit bars

Cartoner for fruit bars

VBS1501

| Task | Transporting, grouping and cartoning of packaged fruit bars |

| Size | M |

| Industry | Baby food |

| Main function | Moving, packaging, other |

| Interfaces | |

| Degree of customization | Standard |

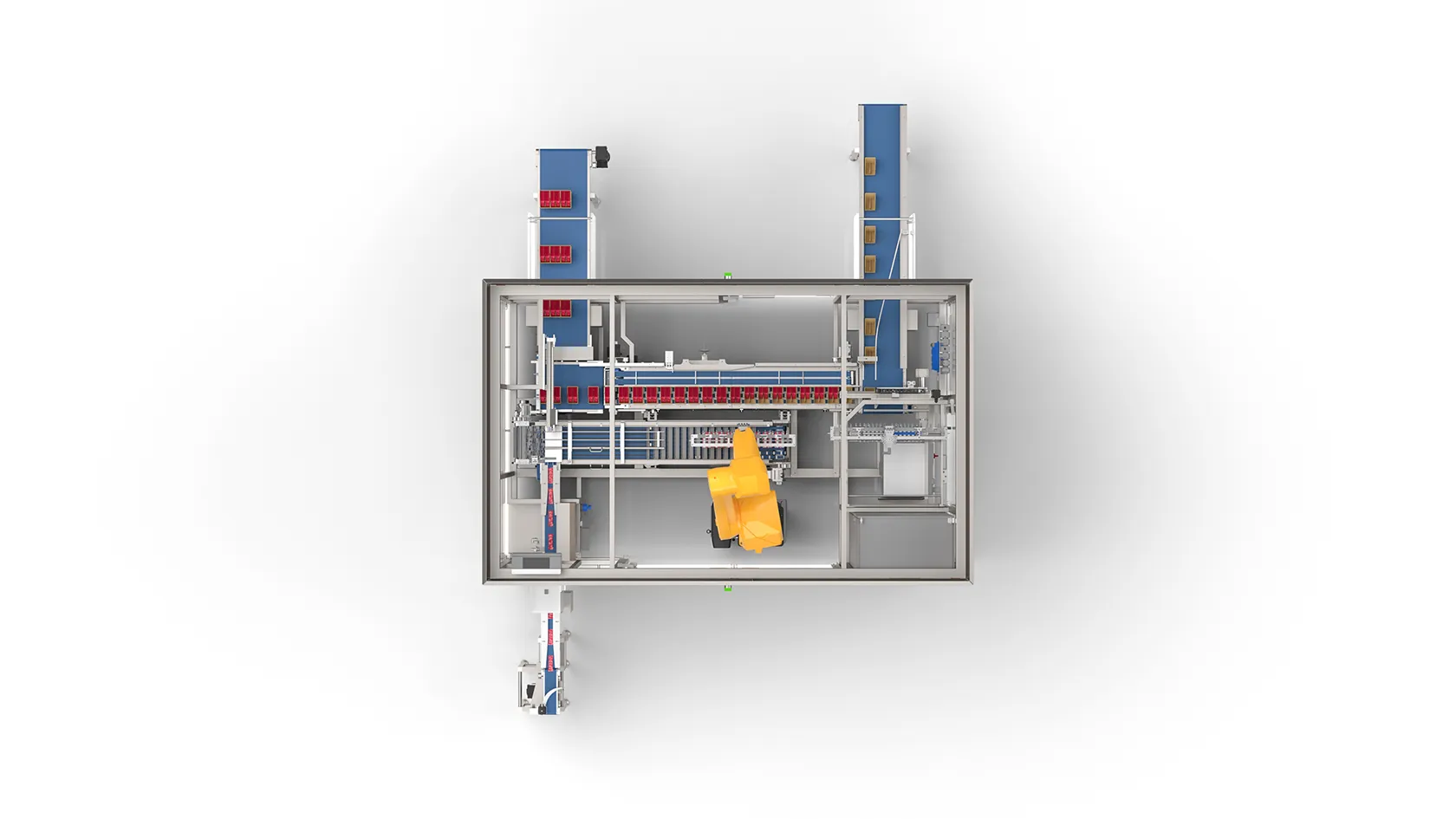

Feeding boxes

Discharge conveyor

Feeding bars

Synchronization belt products

Synchronization belt boxes

Tool holder

| Tubular bag packaging (bar) | up to 260 pieces/min. |

| Folding box (open) | up to 12 pieces/min. |

| Challenges | 6 different bar formats 9 different carton formats |

Hier kommt ein kurzes Zitat des Kunden rein.

This project involved the grouping and packaging of bars.

The fruit bars are fed to the packaging line from the flow-wrapping machine. On the acceleration conveyor, they are detected by a camera control system and defective products are blown out sideways.

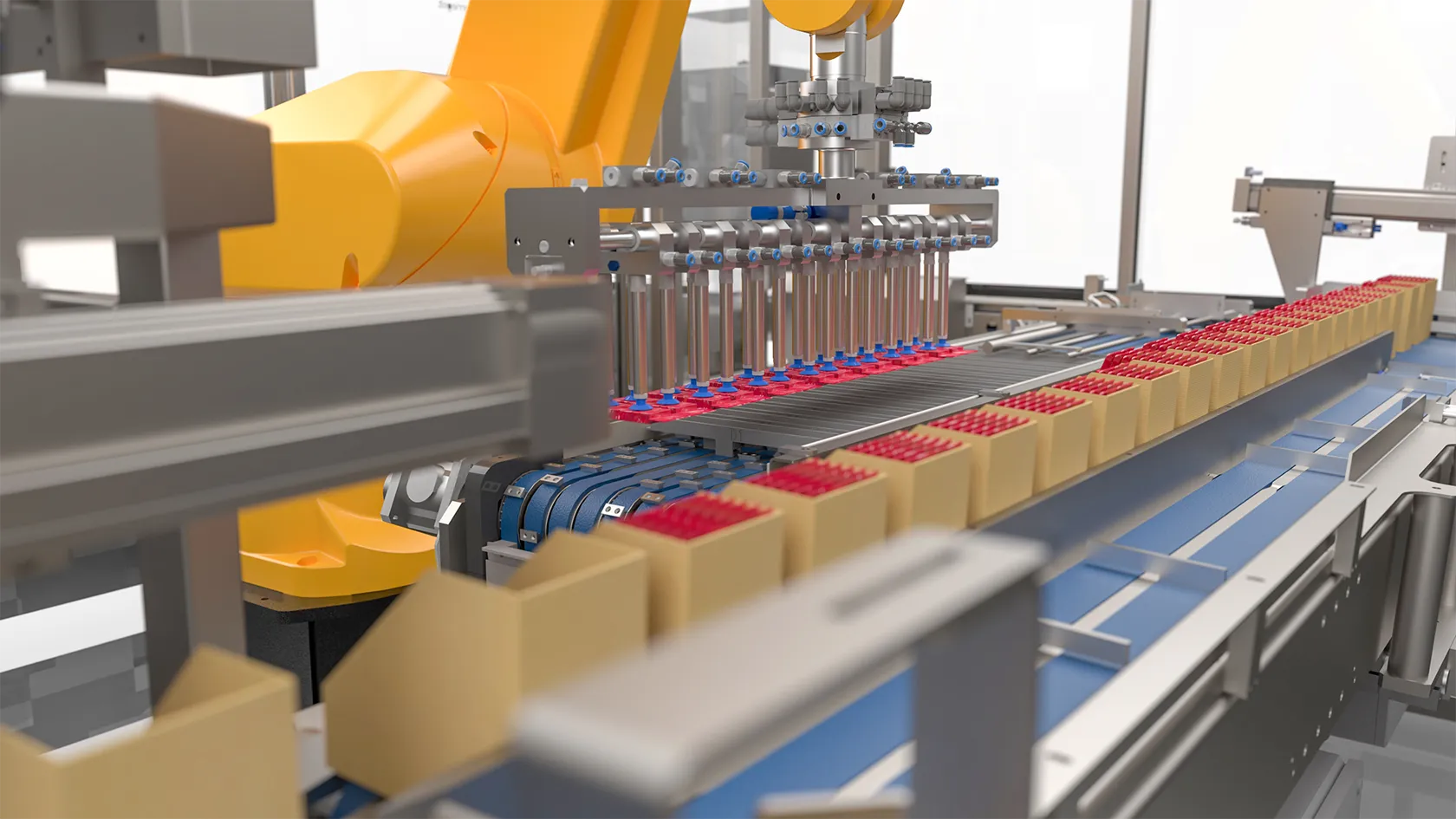

The bars are loaded into an indexing conveyor and grouped into 10, 14 or 16 compartments and conveyed to the robot. The robot has two tools that can be changed automatically via a quick-connect system, depending on the format selected.

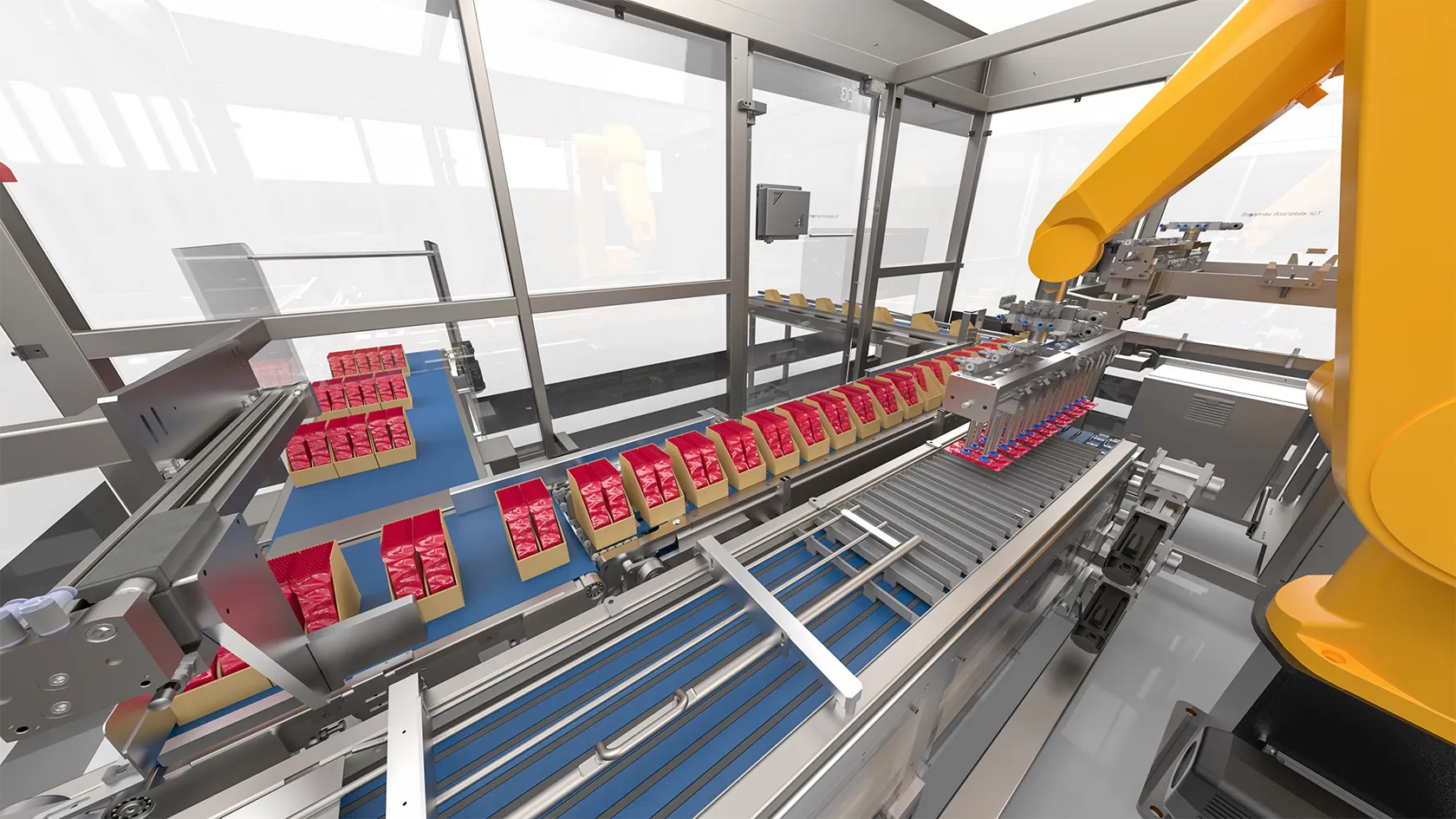

It removes the bars and places them horizontally or vertically in the open folding boxes. With vertical box formats, 7 boxes are always loaded at once. Horizontal formats are always loaded two at a time.

The boxes accumulate at the end of the belt and are pushed onto the discharge conveyor.

| Degree of customization | |

|---|---|

| Industry | , |

| Machine size | |

| Machine type | , , , , |

| Main function | , , |

| Performance | , |

| Products | , , , |