Cartoner for bars

Cartoner for bars

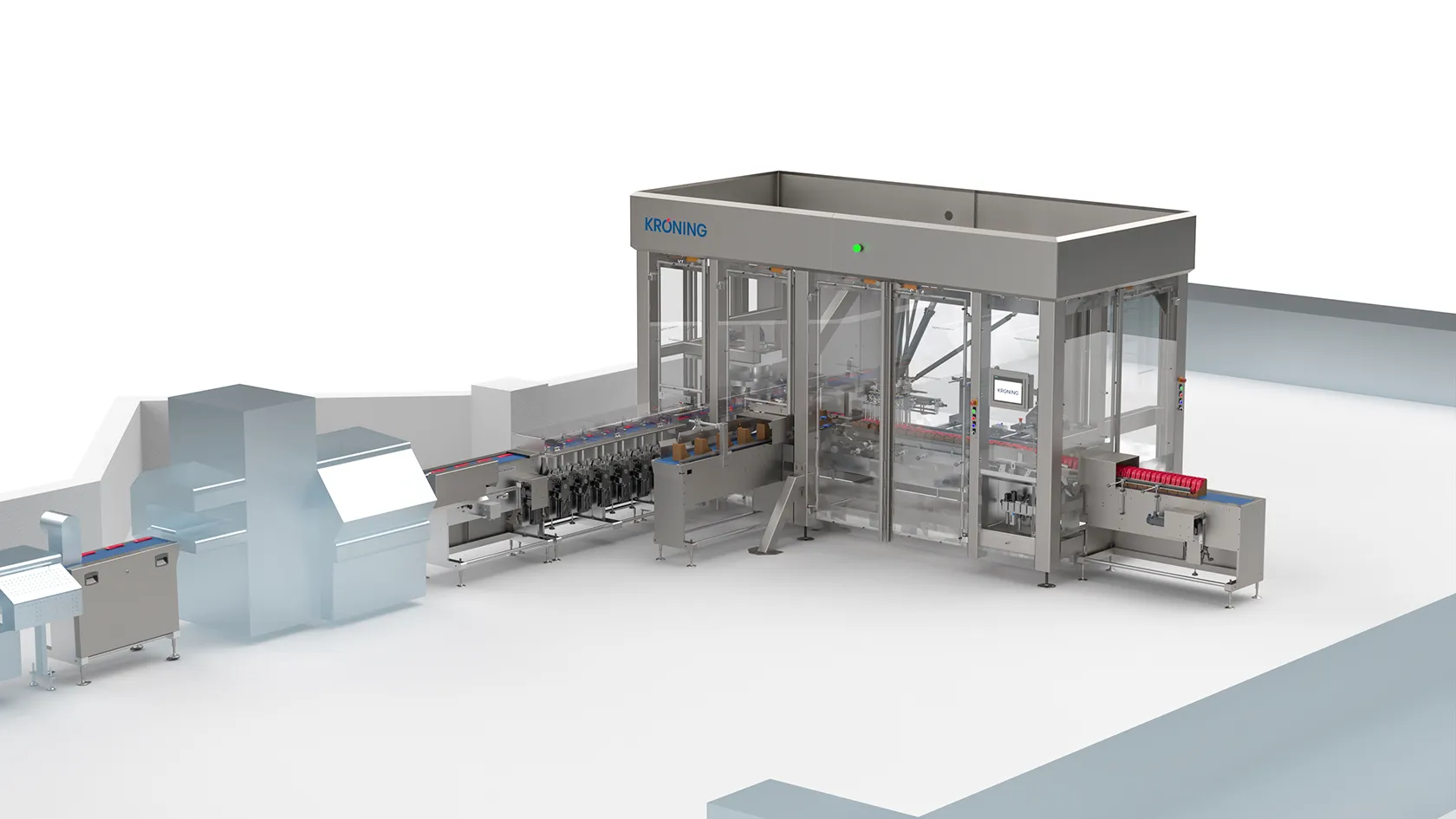

VBS2005

| Task | Transporting, grouping and cartoning of packaged and unpackaged bars |

| Size | M |

| Industry | Bars |

| Main function | Moving, packaging, others |

| Interfaces | |

| Degree of customization | Standard |

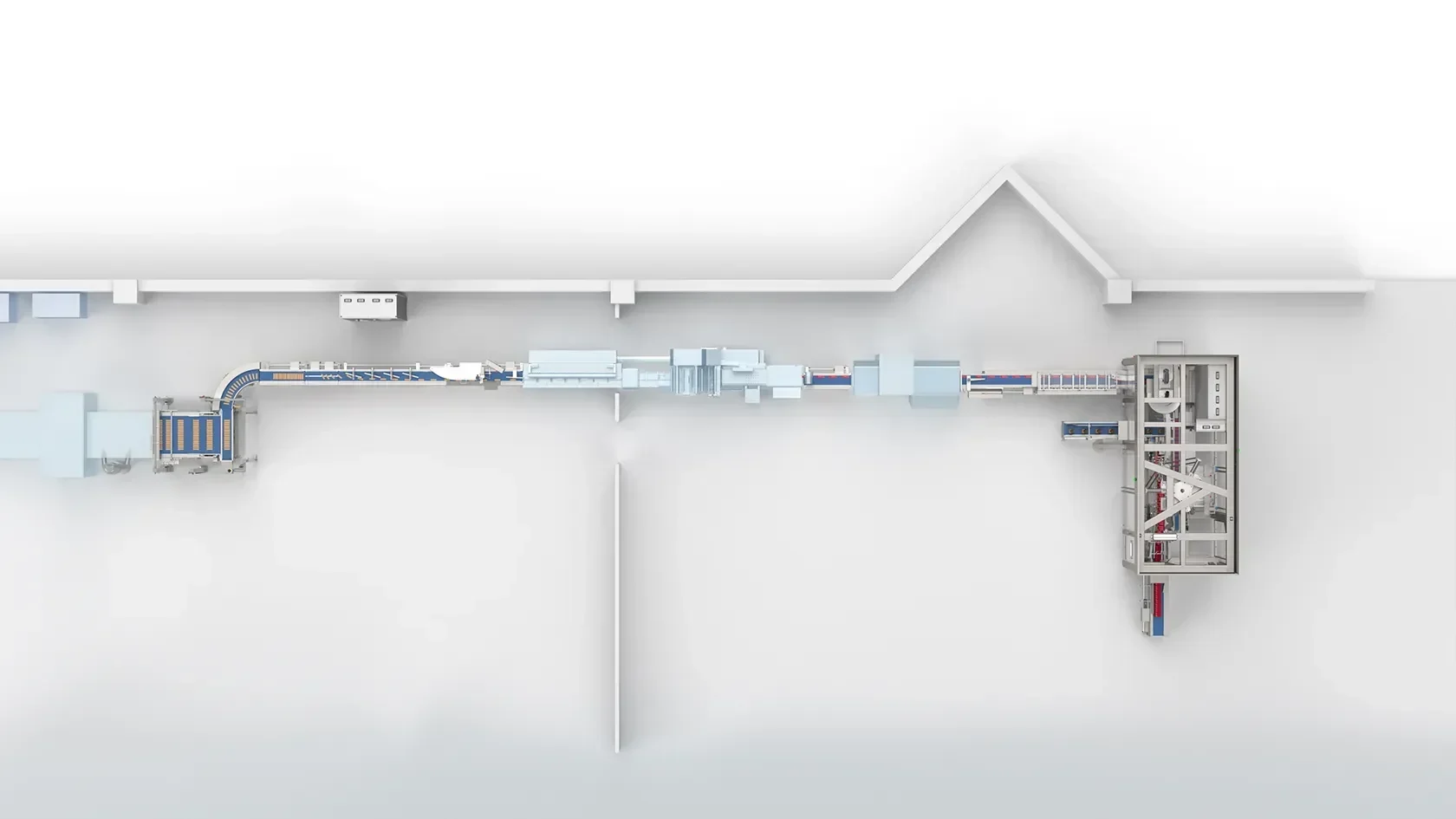

Interface bar press

Transfer to curved belt with return edge

Pre-turning conveyor

Tubular bag machine

Tubular bag machine

Conveyor cascade

Rotary transfer machine

Cartoning robot

Feeding boxes

Output filled boxes

| Tubular bag packaging (bar) | up to 450 pieces/min. |

| Bars (various flavors) | |

| Folding box (open) | up to 20 pieces/min. |

| Challenges | 5 different bar formats 9 different carton formats |

Hier kommt ein kurzes Zitat des Kunden rein.

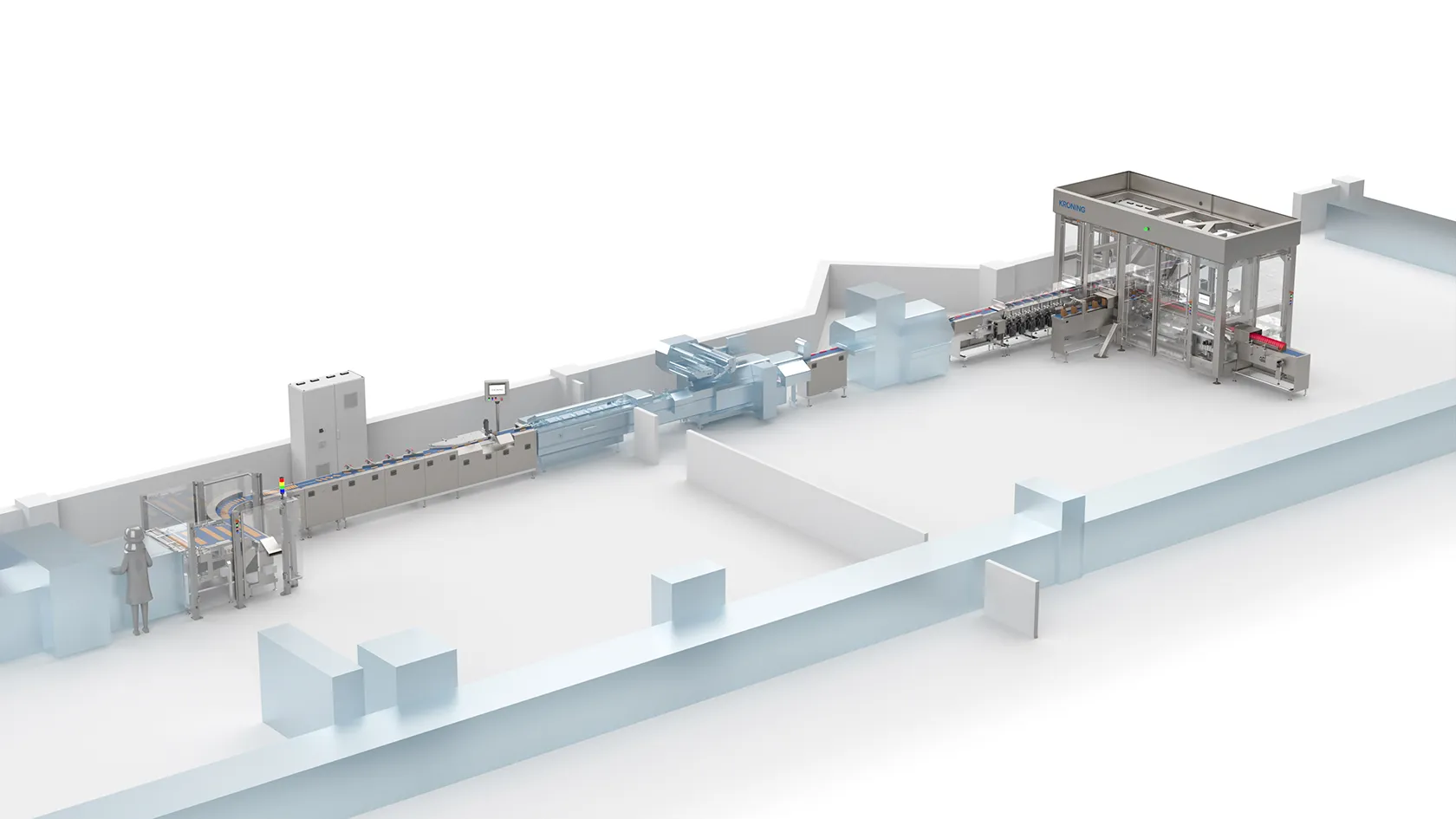

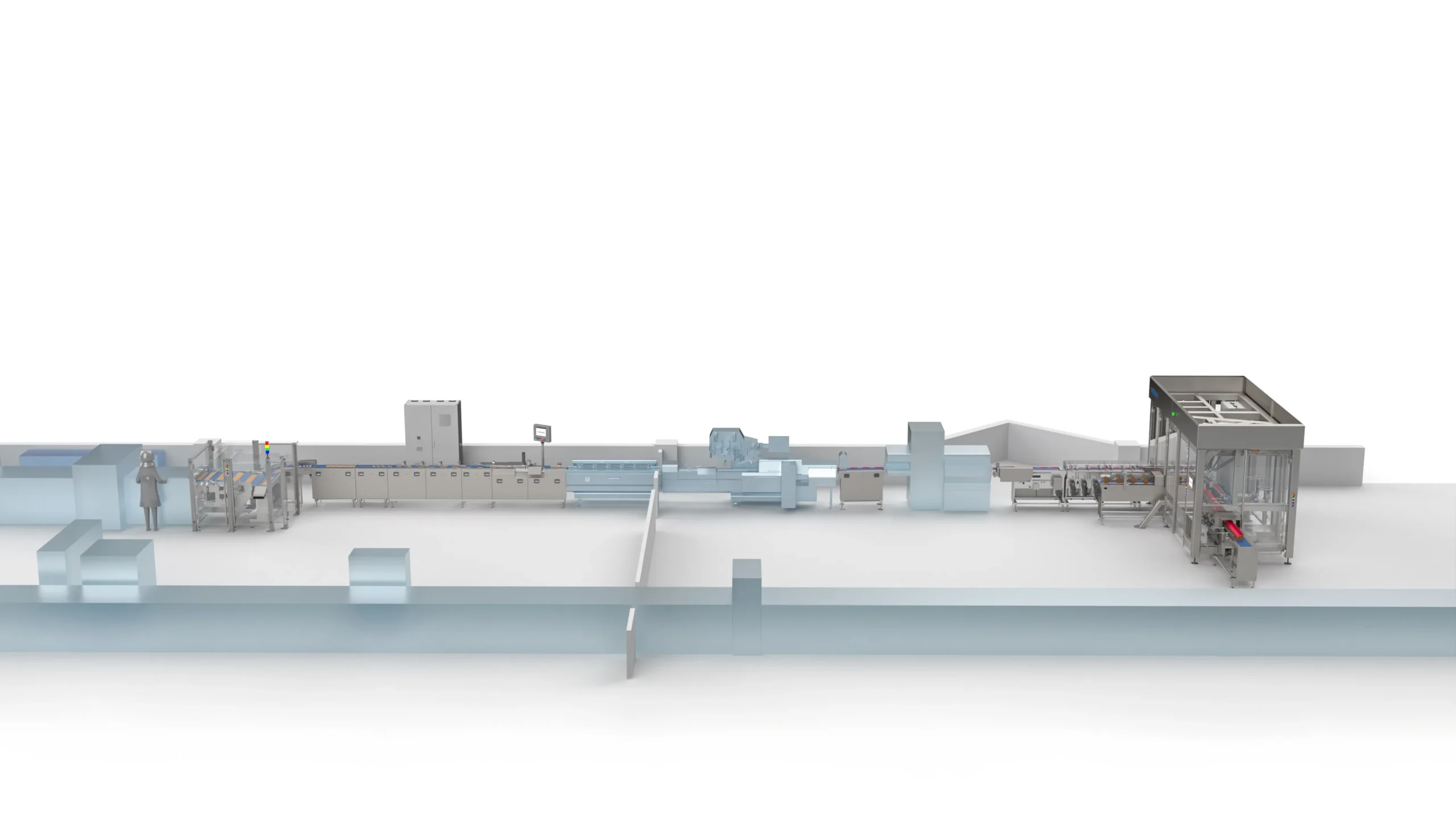

This project involved the feeding of unpackaged bars to a form-fill-seal machine and the grouping and packaging of already packaged bars.

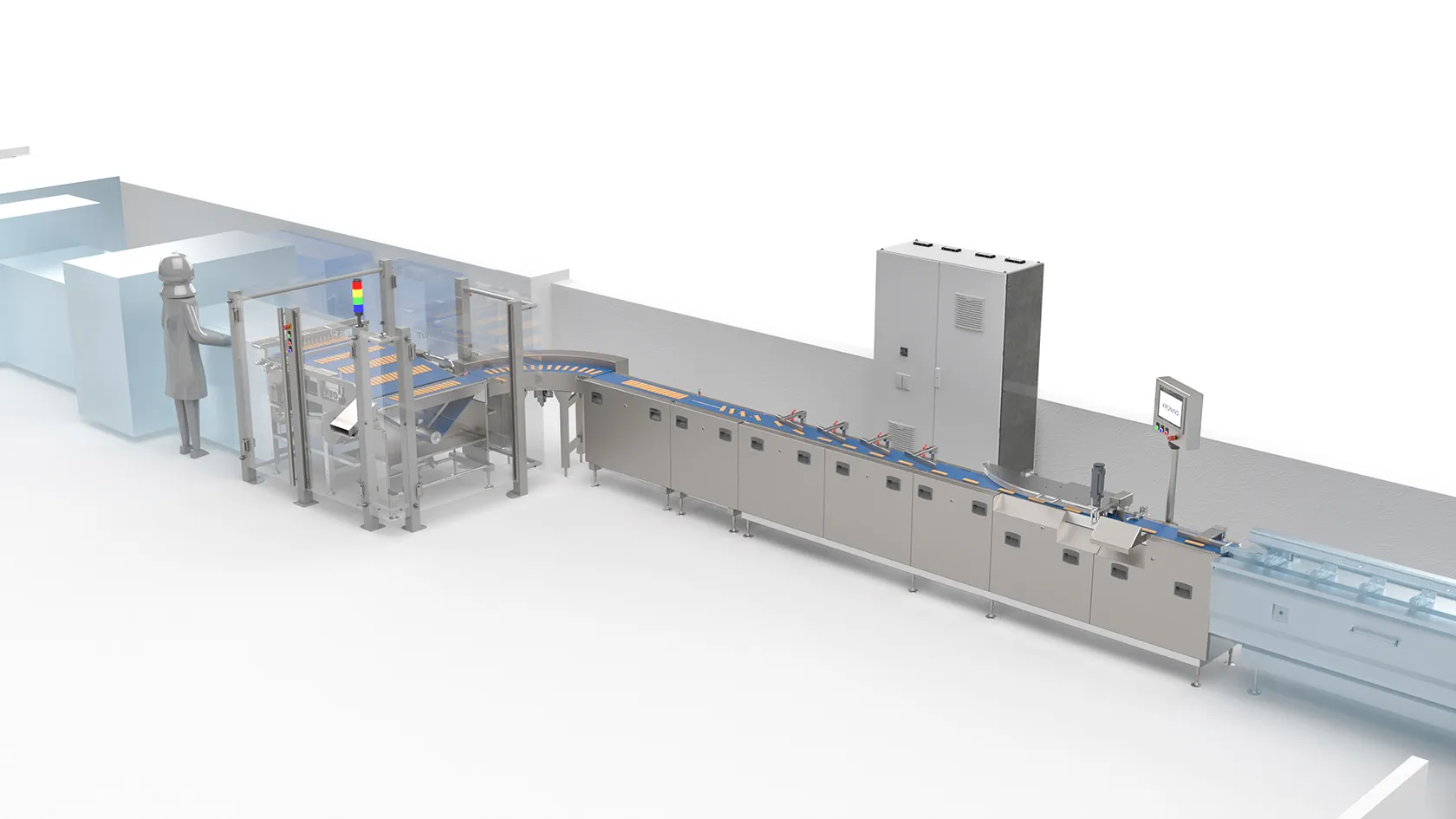

Feeding unpackaged bars

16 products are fed in a row from the upstream bar system onto the retracting edge conveyor. The bars are aligned flush with a stopper edge and placed on the discharge conveyor by the retracting edge.

If there are faults in the downstream systems or when the system is being emptied, the products can be discharged here. Fault-free bars are transferred to the curved belt and fed to the form-fill-seal machine via a pre-twisting belt and several chicanes.

Feeding pre-packaged bars

The bars are fed to the cartoning cell on a belt. The corner turret picks them up and sets them down on the cartoning indexing conveyor. The delta robot removes the bars and places them in the box in a horizontal position.

The orientation of the boxes on the box feed conveyor influences the final orientation of the bars.

At the end of the box conveyor, the filled boxes are removed by an operator.

| Degree of customization | |

|---|---|

| Industry | , |

| Machine size | |

| Machine type | , , , , , , |

| Main function | , , |

| Performance | , |

| Products | , , , , |