Can assembly and packaging line

Can assembly and packaging line

BOK2201

| Task | Final assembly, packaging and palletizing of cans for the chemical industry |

| Size | L |

| Industry | Chemical industry |

| Main function | Moving, assembling, packaging |

| Interfaces | |

| Degree of customization | Standard |

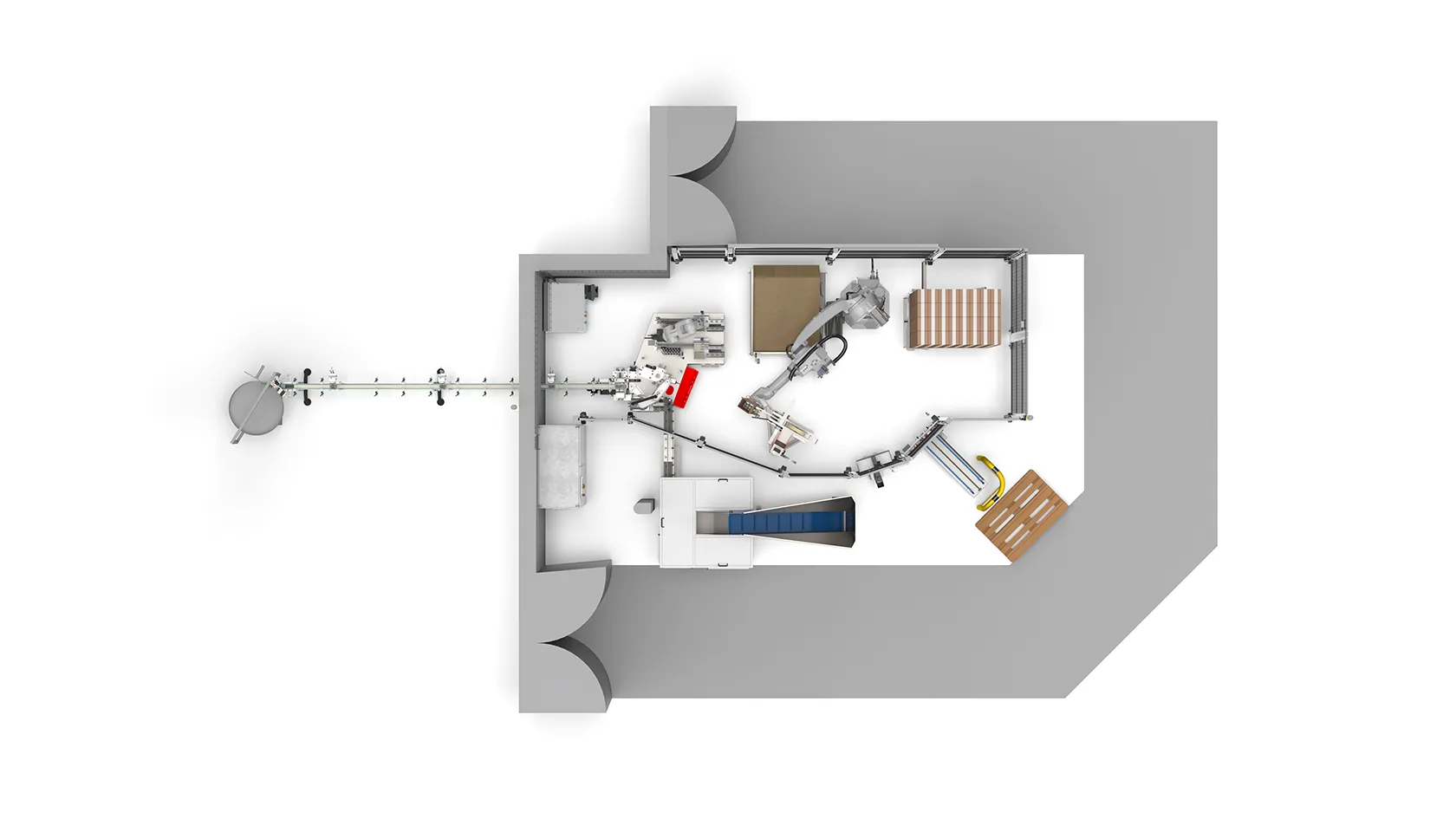

Palletizing

Interlayers

Assembly

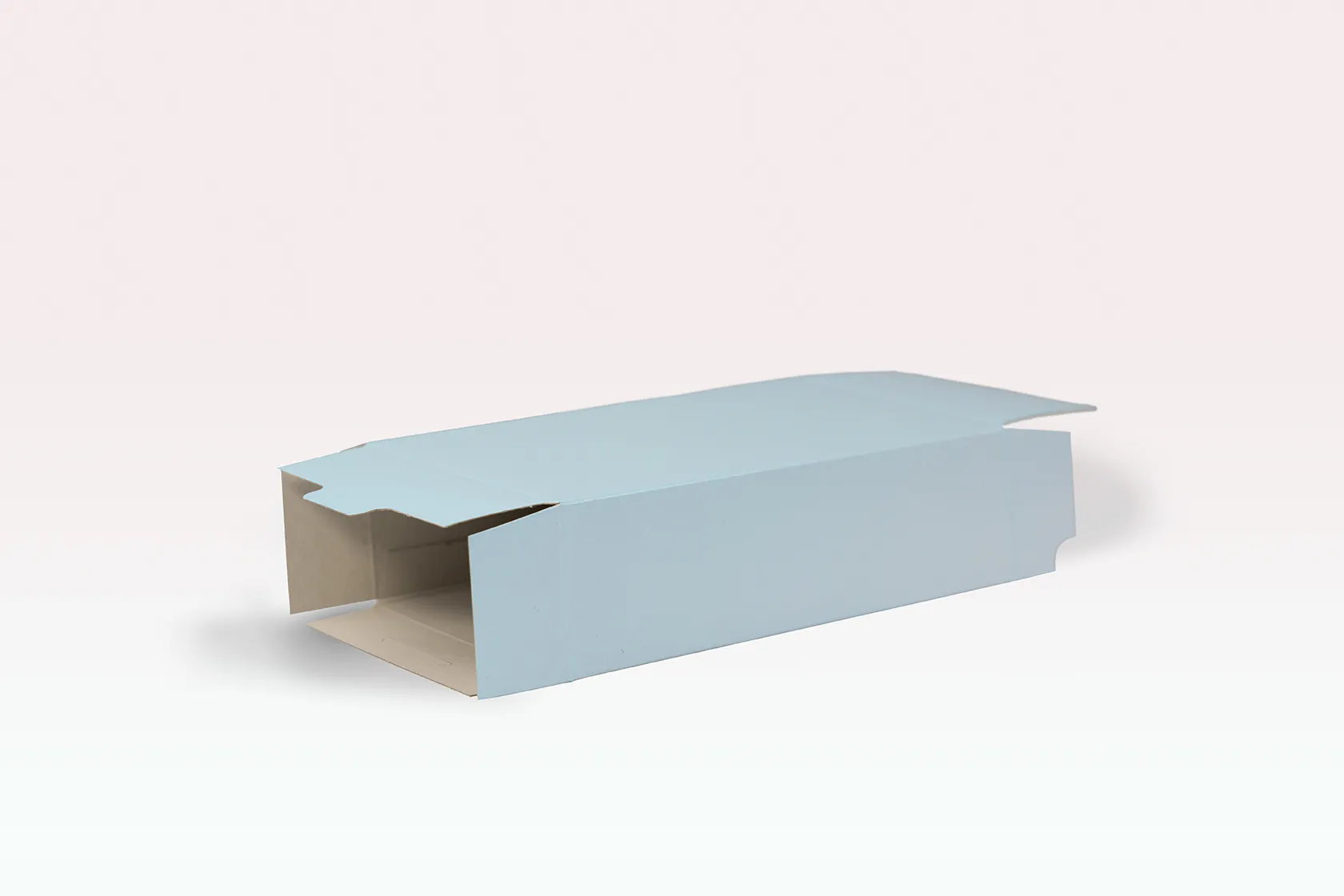

Cartoning

Feeding caps

Feeding cans

Output

| Metal can | up to 60 pieces/min. |

| Plastic cap with nozzle | |

| Side-loading carton | |

| Challenges | Limited space Complex tool for cartoning, palletizing and carton erection |

Hier kommt ein kurzes Zitat des Kunden rein.

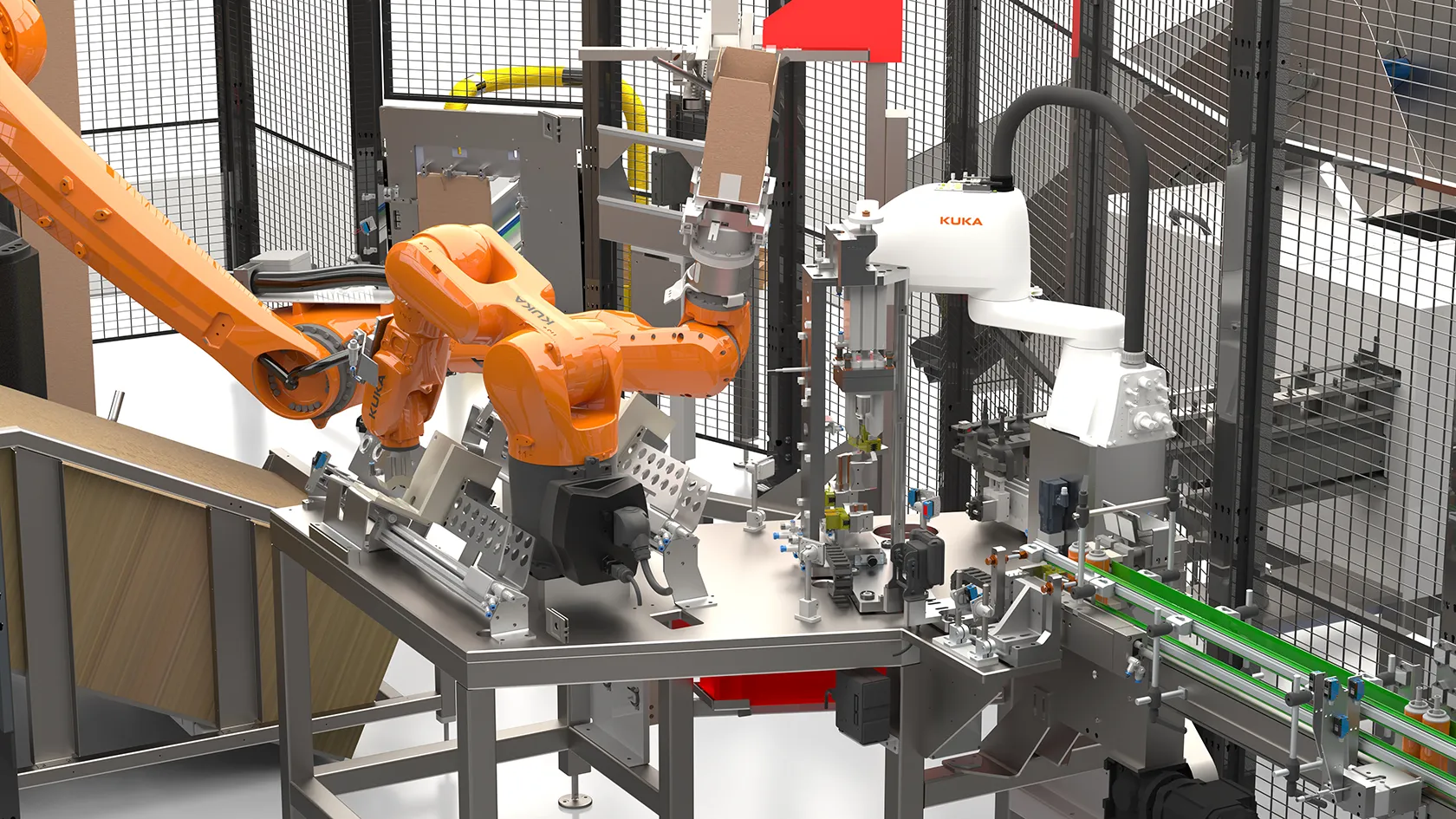

This project involved the final assembly, packaging and palletizing of cans for the chemical industry.

Filled cans are fed to the system in a single row. At the end position, the assembly robot removes the cans and places them in the assembly unit. At the same time, caps are fed from a bunker and placed on the can, after which they are pressed on.

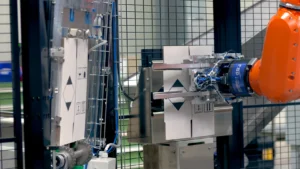

After the can has been removed from the assembly unit, it is taken by the robot and placed in front of a box. Depending on the format, a stack of 6 to 12 cans is formed here and pushed into the box. The palletizing robot removes the filled box, pulls it through the gluing unit and places it on a pallet according to the packing pattern.

After each complete layer, the robot also removes a slip sheet and positions it on the pallet.

| Degree of customization | |

|---|---|

| Industry | , |

| Machine size | |

| Machine type | , , , , , , , , , , |

| Main function | , , , |

| Performance | |

| Products | , , , , |